Introduction

Do you want to get rid of the traditional cutting techniques that are slow and do not produce precise results? Do you want to work quickly and with minimal effort while cutting through different materials? Conventional saws and torches may be unwieldy and laborious to use.

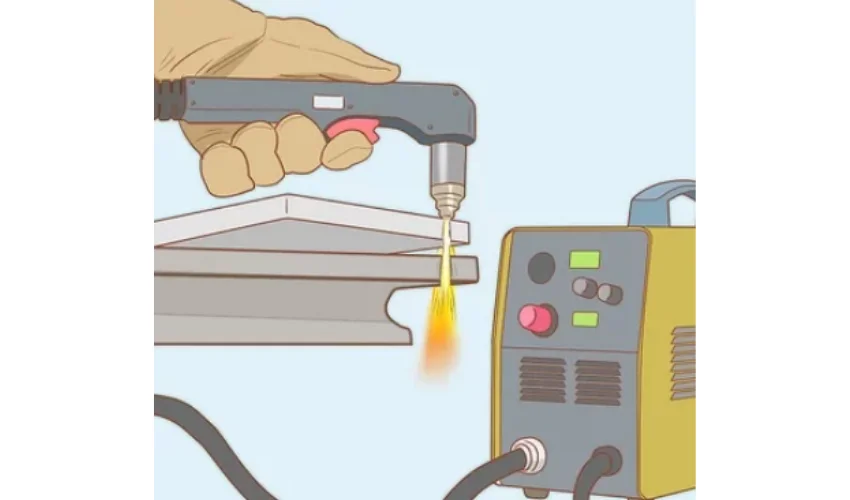

Moreover they frequently possess sharp edges that require constant retouching. Plasma cutter, a leading edge in cutting technology, walks in. At a super high speed and sharp precision, a plasma cutter gives you the opportunity to effortlessly cut objects with smooth pleasing edges.

But here’s the catch: understanding how plasma cutter works can be challenging. Rest assured, this article gives you a detailed explanation of “what is a plasma cutter used for”. Let’s get started.

Table of contents

- Introduction

- Part 1: What is a Plasma Cutter Used for in Construction and Metal Fabrication Industries

- Part 2: What is a Plasma Cutter Used for in Automotive Industry and Vehicle Modifications

- Part 3: How Plasma Cutters are Used by Metalwork Artists

- Part 4: What is a Plasma Cutter Used for in the HVAC Ductwork Industry

- Part 5: Uses of Plasma Cutters in Shipbuilding and Maritime Industries

- Part 6: How Plasma Cutters Can Be Used for DIY

Part 1: What is a Plasma Cutter Used for in Construction and Metal Fabrication Industries

Helpful when cutting thick steel sheets

Plasma cutters are very much needed in the construction and metal fabrication industries, especially when working with thick steel sheets. However, they can produce high-power plasma arcs, which easily cut the thick steel, enabling you to work faster than other traditional methods. From producing structural steel beams to slicing heavy plates for construction projects, a plasma cutter allows you to cut parts with accuracy and speed, thus making your materials perfectly fit the specifications.

How Plasma cutter can be useful when shaping metal components

Concerning the shaping of metal components, plasma cutters stand out in their capacity to be adaptable and accurate. Through the control of cutting speed and intensity, shaping the metal parts according to your specifications becomes manageable. Whether it is fine patterns or just outlines, a plasma cutter will help you improve the quality of your making and the efficiency of your fabrication.

Function as a multipurpose tool such as cutting metals (steel, iron, and aluminum)

Plasma cutters differ in their beneficial use while working with metals such as steel, iron, and aluminum. This makes them a must-have equipment for any metal fabrication shop or construction site where we find different materials. If you are working with steel structures, iron gates, or aluminum panels, a plasma cutter will allow you to cut all types of metal with comfort and efficiency.

Read this short article on how to use a plasma cutter.

Part 2: What is a Plasma Cutter Used for in Automotive Industry and Vehicle Modifications

How plasma cutting is useful for trimming metal panels

Plasma cutters have brought the automotive industry and custom fabrication to a halt because of higher cutting accuracy and speed. From creating custom body panels, exhaust systems, and intricate designs to precisely bringing your vision to life with speed, a plasma cutter is your gateway.

For making customized spare parts

In a good example, plasma cutters are inevitable for such tasks as cutting out rusted sections of car frames, designing precise openings for new components or shaping incomparable designs for custom vehicles in the automotive industry. Talking about vehicle modifications, plasma cutters are the most effective at cutting thick metal with only a little effort and with their help, you can modify chassis, create custom brackets or make unique accessories.

To perform accurate cuts efficiently

Also, plasma cutters produce clean and precise cuts that require less finishing work. This not only saves your time but also guarantees an appealing outcome. Plasma cutters go for various automotive applications, such as restoring classic cars or building race cars from scratch.

Part 3: How Plasma Cutters are Used by Metalwork Artists

What is the significance of the plasma cutter to artists?

Plasma cutters are the most important tool for metalwork artists as they provide unmatched precision and flexibility in the designing of fine art. Equipped with a plasma cutter, you can simply cut through steels, aluminum or copper materials and convert your splendid ideas into reality without any problem.

Helpful in creating complex artwork

A major strength of using a plasma cutter in art is its capability to process difficult shapes. Whether you are creating detailed sculptures or complex patterns, the accuracy of the plasma cutter enables you to cut to immaculate details. This means you can get more complex textures and fine lines, which may not be possible with traditional cutting methods.

Not only this, plasma cutters provide artists the opportunity to work on a wide range of materials and thicknesses, making it easy for you to be creative and explore different textures and finishes in your art. A plasma cutter can be used to create large-scale installations or produce small items like jewelry pieces that require precision and cutting power.

Generally, plasma cutters give metalwork artists an opportunity to go beyond their creativity because of the precision, flexibility and speed in which they do the work. Now, you have access to a plasma cutter. You can unleash your power in metalworking and take your artistic creation to another level.

Part 4: What is a Plasma Cutter Used for in the HVAC Ductwork Industry

Importance of plasma cutter when cutting and shaping

In the HVAC ductwork industry, plasma cutters perform a key function in cutting and shaping processes. As for cutting, their effect cannot be ignored. A plasma cutter works quickly on any ductwork fabrication materials, whether galvanized steel or aluminum. This high speed and promptness save you precious time and resources and help you to complete all project tasks on time.

Importance of precision cuts for easy installations

Apart from this, precision cuts enable the easy installation of the ducting HVAC system. The plasma cutter will give you unrivaled accuracy, giving you a smooth, clean edge that will fit the other components perfectly once you assemble them. This precision further minimizes the need for additional adjustments or modifications, thus saving installation time and labor costs.

On the other hand, the plasma cutter helps create complex shapes and curves, which consequently enables flexibility in the design of the ductwork. Whether you have simple straight lines, curves, or complex patterns, a plasma cutter helps you for excellent results easily. This uniqueness enables you to deal with the specific needs of each HVAC system to achieve optimum performance and efficiency.

In conclusion, plasma cutters are essential equipment in the HVAC ductwork industry because of their high cutting speed, precision, and versatility for the sheet metal fabrication and installation process.

Part 5: Uses of Plasma Cutters in Shipbuilding and Maritime Industries

How is it used to build ship structures?

Plasma cutters change the marine and shipbuilding focus with their speed and accuracy. They are widely used in ship structures to cut a metal sheet into a desired shape. Whether cutting through thick steel plates or creating detailed components, it’s an easy task with minimal effort. This was previously a tedious process, now simplified by using plasma technology.

How has it increased the efficiency of the industry?

Plasma cutting greatly contributes to shipbuilding efficiency. Ponder the amount of time that would be saved when compared to the old process using oxy-fuel cutting. Hence, the plasma cutters help you do the smoother cuts within a fraction of the time. This cost-effectiveness leads to considerable savings as well as increased productivity. You will finish projects faster, making deadlines a breeze and freeing resources for more vital activities.

Ability to achieve deadlines while maintaining quality standards

Meeting timelines together with quality control is crucial in shipbuilding. Plasma cutters outperform in this field. They can cut accurately and provide clean cuts each time so that joints are perfect and there is no rework. Plasma treatment does not compromise quality over speed. In contrast, you are pursuing them together, hence having the plasma cutters of choice in shipbuilding and maritime industries.

Part 6: How Plasma Cutters Can Be Used for DIY

Growing popularity among homeowners

Plasma torches attract many homeowners due to their versatility and ease of use. Through technological progress, these old fashioned tools have now become readily available for home consumers. Be it a home renovation or a creative job, you can depend on your plasma cutter as your main tool. This is from cutting metal sheets for roofing to shaping decorative pieces for the design of interiors, the options are infinite. By acquiring a plasma cutter, you are equipped with the tools to maneuver different DIY tasks effortlessly and accurately.

Demand for custom metal furniture

The increased need for bespoke steel furniture has resulted in the generation of the interest of DIYers in plasma cutters. Instead of choosing mass-produced substances, most homeowners prefer artsy pieces whose designs match their tastes and preferences. You can now explore your inner designer and design custom-made furniture with a plasma cutter. Whether it is a minimalist coffee table, a decorative headboard, or industrial-style shelving, you know how to make your visualization come true. Developing advanced skills in metal crafting using a plasma cutter is an excellent way to enhance your decor at home and demonstrate your uniqueness.

Create your garden artwork

Use your garden area as a blank canvas to create an artistic paradise from garden artwork using a plasma cutter. Whether you choose whimsical little sculptures or intricate trellis designs, you can add a creative touch to your garden with highly personalized pieces. With a plasma cutter, you can easily and without much strain cut metal to create beautiful patterns and shapes that are very detailed. Whether you are a novice or a skilled DIYer, playing with garden artwork is a perfect way to express your creativity and beautify the appearance of your outdoor place. Enjoy the versatility of a plasma cutter and expand your creative limits to add unique pieces to your garden.

Conclusion

Now you have in-depth insights on “What is a Plasma Cutter Used for”. Plasma cutters are inventive devices that are used for cutting metals with precision. Understanding their application is key to getting the most out of them. Now you know why you need to pick the right plasma cutter. Ensuring better cutting and safety you should buy a good product at any cost. VEVOR has a variety of trusted plasma cutters designed to meet different needs. With the right cutter, you will save time and get a quality output. Do your part and check out VEVOR’s range of plasma cutters to find the one that suits you best today. Take your metalwork to the next level with perfection and effortlessness.