| Difficulty Level | Estimated Cost | Duration |

|---|---|---|

| 8 out of 10 | $150 – $200 (Depends on the price of the Vaccum pump and the required tools) | 5 hours |

Vacuum pumps are typically used to create and maintain a vacuum environment for several processes. It plays a critical role in multiple industries and has a variety of applications. For example, vacuum pumps are used in manufacturing, research and development, medical and healthcare, energy and power generation, food processing and packaging, HVAC systems, and many more applications. No matter your profession, if you are interested in gaining knowledge about vacuum pump technology, this article is carefully curated for you only.

There are multiple vacuum pumps available in the market. But if you ask us which one is the best, we’ll definitely say – the VEVOR Vacuum Pumps. VEVOR is a leading brand that offers premium tough, quality equipment and tools at incredibly low prices. What makes the VEVOR Vacuum Pumps the best on our list is its heavy-duty vacuum pump and premium vacuum chamber with easy monitoring and cooling system. Let’s learn more!

Why Do You Need VEVOR Vacuum Pumps?

Vacuum pumps are mechanical machines that are designed for removing gas molecules from a confined space and setting up a partial or almost complete vacuum environment. Drawing out air and other gases can lower the pressure within a system. This results in a very controlled environment for several processes. Vacuum pumps are mostly used in manufacturing, food processing, packaging, research laboratories, medical applications, etc.

1. Applications

Vacuum pumps are one of the fundamental devices used in numerous applications on the ground that their incredible ability to create and maintain vacuum environments. Vacuum pumps play a crucial role in degassing processes, distillation, drying, removing contaminants, and many more.

Not only in the field of manufacturing, but these pumps are also widely used in the research and development sector for conducting scientific experiments, handling delicate substances, enabling precise measurements, enhancing efficiency and performance, etc. It is also frequently used in the medical field for blood collection, wound drainage, and suctioning during surgeries.

2. Safety Precautions

Not being careful while using vacuum pumps might result in a hazardous situation. So it is better to take safety precautions before setting up and using vacuum pumps. Always go by the safety guidelines provided by the manufacturer and wear personal protective equipment (PPE) while using the pump if that’s necessary. Be careful of the hot surfaces and rotating parts of the pump.

Also, before using the pump, make sure to learn the precautions in order to avoid any accidents. Ventilation is another important aspect of using the vacuum pump appropriately. Make sure there are enough spaces around the pump so that it can dissipate the heat that was generated due to its operation. Overheating will decrease the pump’s performance efficiency, so proper ventilation must be provided.

Our Vacuum Pump Recommendation: VEVOR Vacuum Pumps

There are multiple reasons why choosing VEVOR Vacuum Pumps is the best decision. Here are some reasons why you should purchase it-

1. Heavy-Duty Vacuum Pump

Heavy-duty aluminum alloy with outstanding heat dissipation and durability is used to make the pump. For steady functioning, a robust copper motor is employed. Additionally, it has a non-oil flow-back design to prevent chamber contamination.

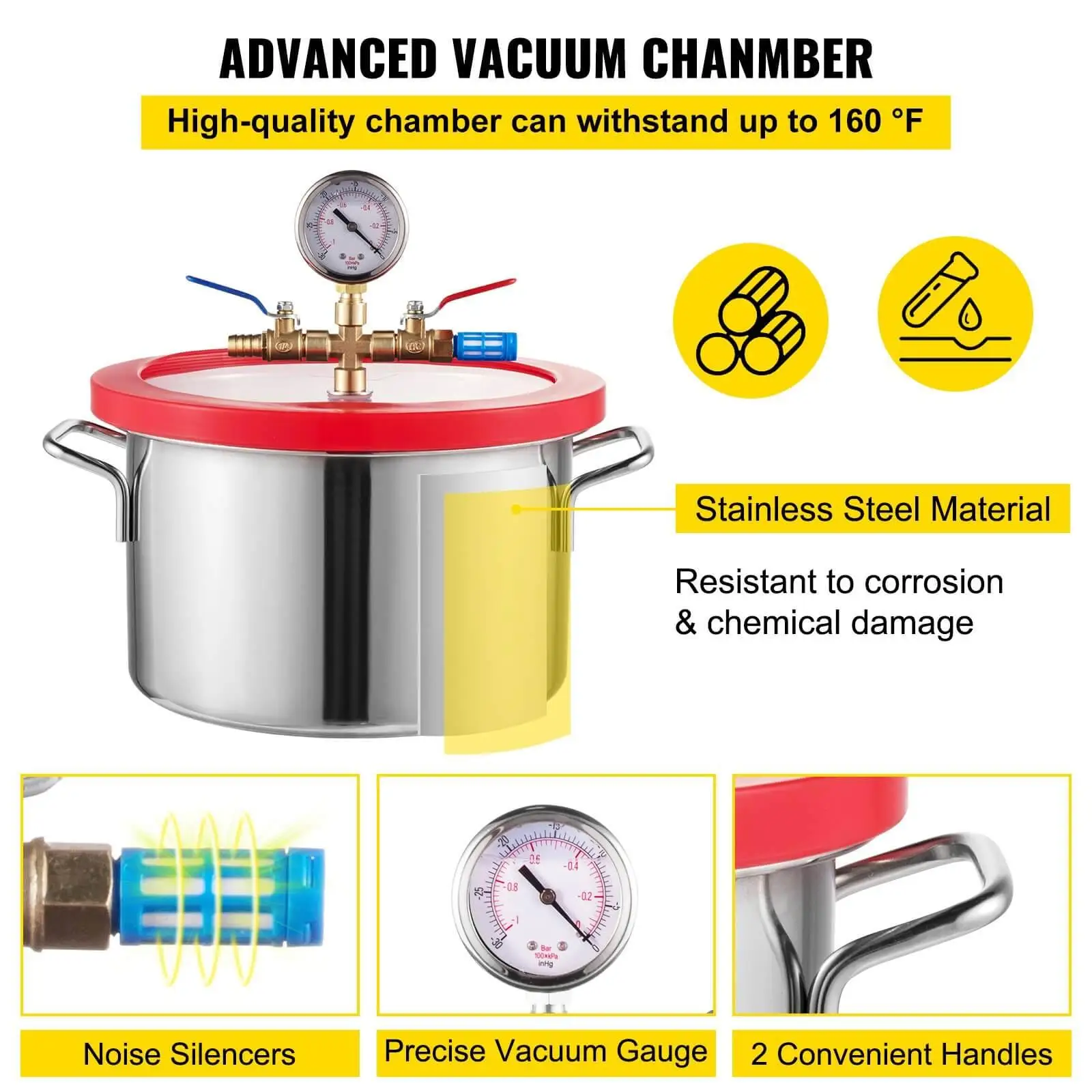

2. Premium Vacuum Chamber

The vacuum chamber is constructed of highly durable stainless steel. a single silencer is included to help with noise reduction. The chamber is shielded from dust and particles by an air filter.

3. Easy Monitoring & Cooling

It has an oil viewing glass so you can easily check the oil levels and prevent an oil shortage. The pump is cooled using intelligent radiators, which also help to keep items from burning. A heat protection feature that is incorporated into the device will stop it from burning.

4. Wide Application

A vacuum pump and vacuum chamber of the highest quality are included with this device. With its ergonomic grip, it is incredibly comfortable and portable. This equipment is ideal for vacuum packing, industrial production, home air conditioning, and vehicle servicing. Additionally, this kit is utilized to distort silicone, essential oils, epoxy, polyurethane, and other materials.

Step-by-Step Process of a Vacuum Pump

Step 1: Get Familiarized with the Vacuum Pump

The first step of using a vacuum pump is to get familiarized with its setting. Read the manufacturer’s user manual of the vacuum pump and learn about its various parts. Try to understand its core features, safety precautions, specifications, warnings, etc. Find out if there are any specific instructions mentioned that you should be aware of.

Step 2: Set Up the Device

By following the user manual, prepare the setup first. Find out which specific tools you might need to set up the device. You might need appropriate tubing, connectors, and fittings for connecting all the parts of the pump. Secure all the connections in order to prevent oil leaks.

Step 3: Connect the Pump to the Power

A vacuum pump cannot operate without a continuous power supply. So connect the device to the power supply and then switch it on to check whether the connections are correct. Don’t forget to follow the user manual before connecting it to the power supply.

Step 4: Test the Setting

Now check if the system is working properly or not. Once you have turned on the power supply, if the connections are right, then it will start pumping. It will start its process of vacuuming the system. Monitor its operation to find if there is any abnormality.

Step 5: Pumping Speed and Pressure Adjustment

In the next step, check the pumping speed and pressure of the system. Check if those are appropriate for your specific environment. If not, then adjust the speed and pressure of the vacuum pump according to your requirements.

Step 6: Monitor the System

After connecting it properly and starting its operation, it’s time to monitor if it’s working correctly as well as efficiently. Make sure there are no abnormalities in its performance. If you notice any anomaly, take all the necessary measures to remove it.

Step 7: Maintenance of the System

Maintaining the system is one of the most crucial vacuum pump steps. If the device is not well-maintained, it will not provide satisfactory output as it is not able to work effectively. Follow the VEVOR’s maintenance guidelines for their vacuum pump and gather all the necessary tools for routine maintenance. Regular vacuum pump maintenance includes changing the air filters regularly, lubricating the pump rotator, regularly cleaning the device, etc.

Step 8: Shutdown the System

Lastly, once the device completes its operation, shut down the system according to the manufacturer’s instructions. You will most likely have to turn off the power supply switch, release the vacuum pressure, and then disconnect the vacuum pump from the system.

Required Tools and Materials

Things You Will Need

- A vacuum pump: The VEVOR Vacuum Pump is the fundamental tool required for the operation. Make sure that you have the right model and size of pump suitable for your application.

- A vacuum chamber: The VEVOR vacuum chamber serves a controlled and enclosed vacuum environment.

- Tubing and Fittings: These are necessary tools for connecting the vacuum pump to the specific system being evacuated.

- Gaskets and Seals: These are also used for connecting the pump with the system. What type of seals and gaskets are required depends on the pump’s model.

- Power source: VEVOR Vacuum Pumps cannot operate without a power source. Ensure that the necessary power supply is available at all times.

- Maintenance Tools include tools like screwdrivers, wrenches, and lubrication materials for routine maintenance. As routine maintenance of the device is immensely important, these tools are a must-have.

Conclusion

As more advanced technologies and the newest application emerge, the ongoing demand for vacuum pumps grows daily. Doesn’t matter if it’s for scientific exploration in research laboratories pushing all the boundaries or various industries reconstructing their manufacturing processes. It plays a core role in building controlled environments, discarding contaminants, and intensifying efficiency.

In summary, if you are someone working in the field of vacuum system-based industry, it is really essential for you to gather basic knowledge on how vacuum pumps operate, their working principles, key factors, guidelines, etc. Don’t forget to follow their installation step-by-step by reading the user’s manual, operations, maintenance guidelines, and safety precautions to ensure your vacuum pump’s desired performance and durability. With the help of our comprehensive guide as your main reference, you are now prepared with the basic knowledge to maneuver the world of VEVOR vacuum pumps in an assured manner.