Explore VEVOR’s hydraulic pump with our detailed manual and PDF guides, specifically for the double-acting hydraulic power unit. Delve into the intricacies of this powerful hydraulic system that ensures efficient and reliable performance.

This VEVOR hydraulic pump manual provides a wealth of information, including specifications, assembly instructions, maintenance guidelines, and troubleshooting tips to maximize the lifespan of your hydraulic pump.

DC vehicle hydraulic pump matters needing attention

Must ensure that the battery power is sufficient, current 200AN, voltage to match with the machine.

This vehicle hydraulic pump is S3 working system, not continuous operation,30 seconds to start,270 seconds to stop, the maximum working time of 180 seconds, intermittent 360 seconds, continuous working time is too long, will cause motor short circuit or damage.

The power supply is recommended to use 16m’or more than 16m’thick, otherwise, the current is too small, will affect the motor start, resulting in the machine can not run normally.

Table of contents

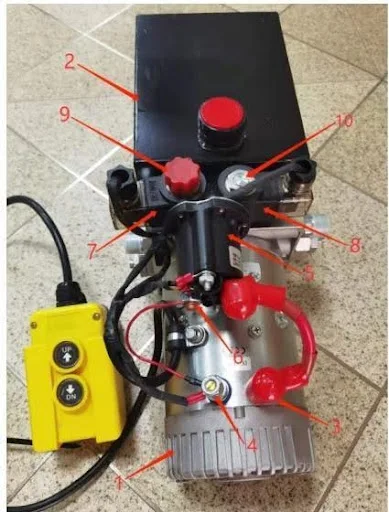

Parts Illustration

- Electronic motor

- Reservoir

- The positive pole of the electronic motor

- The negative pole of the electronic motor

- Relay

- The positive pole of the relay

- Electromagnetic coil A

- Electromagnetic coil B

- two-position four-way valve

- normally closed solenoid valve

- Reservoir return port

- Overflow valve

- Reservoir filler

- Reservoir outlet port

- Overflow valve

- Control box

- Up button

- Down button

- Control wire

VEVOR Hydraulic Pump Installation Instructions: Working principle and wiring method

1. Please fill in hydraulic oil from o13 reservoir filler till it is 3cm to 5mm below the upper surface of the reservoir;

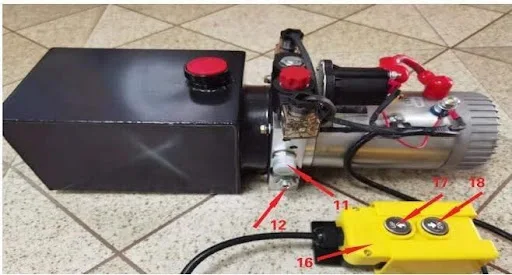

The positive pole of the power supply should be connected to the positive pole of the relay while the negative pole of the power supply should be connected to the negative pole of the electronic motor. The power supply wire must be copper wire 20 to 25 cm2 in cross-sectional area.

2. Wiring method

3. Please connect the power supply correctly and then install the oil pipelines. Then press 17 Up button to turn on the motor. The indicator light of 17 electromagnetic coil A should be lit. And the two-position four-way valve opens to allow oil to be discharged via the reservoir outlet port.

This generates pressure and causes the reservoir to rise. Release the Up button, the motor shall stop work and the oil pump and the reservoir should stay still.

4. By the end of the hydraulic cylinder’s travel, please press 18 the Down button for oil returning. This shall turn on the motor and cause the indicator light of 8 the electromagnetic coil B to light up as well as generate magnetic force to push on the normally closed electromagnetic valve. This allows oil to return and go down.

Common Failures and Troubleshooting

(1)There is no oil rising or lack of pressure although oil has been discharged or there is no oil discharge.

- Please check if the reservoir is adequately filled with oil. The oil uprising pipeline should be connected to 14the reservoir outlet port while the downward pipeline should be connected to the 11 reservoir return port.

- If pressing the UP button and the motor fails to start or work or lacks of reaction, please check if there is a low battery. If the battery is good, then check if the positive ends and negative ends are correctly connected or if there is virtual connection. If so, please strictly follow the working principle paradigm to ensure its correct connection with the power supply;

- If the power supply is correctly connected and the battery is good, but the motor still refuses to start, then you may connect the motor directly to both ends of the power supply to check if there is something wrong with the motor. In this case, the positive end of the power supply should be connected with the positive end of the motor while the negative end of the power supply should be connected to the negative end of the motor. If it still refuses to start or react, it proves that there is a shortcut in the motor circuit or there is a dead battery, please change the motor or charge the battery.

- If the motor starts up when connected directly to both ends of the power supply, then it could be a broken 5 relay or improperly connected switch, please replace the 5 relay or check the status of the switches.

- If the motor starts normally, but no oil discharge or hydraulic cylinder is rising, please check if the indicator light of 7 the electromagnetic coil A is lit or not. If the light is off, please check if the circuit is properly connected.The indicator light of 7 the electromagnetic coil A must be on if oil rises to generate magnetic force and works simultaneously with the motor. If the indicator light of 7 the electromagnetic A is on but there is no hydraulic cylinder rising or oil discharge, please dismantle and take the electromagnetic coil. Then pressing the UP button while plugging the screwdriver or other iron tools inside the electromagnetic coil to check if there is magnetic force. If there is none, then the electromagnetic coil has a shortcut and needs to be replaced.

- If 7 electromagnetic coil A is magnetic but it could not rise, please turn on the 9 two-position four-way valves and take off all of the 10 normally closed electromagnetic valves. Then, clean the valve hole and the filters with diesel or gasoline. Then, install them back and test again. If there is still a problem with normal uprising and oil discharge, then please replace the 9 two-position four-way valve to check if it works properly or not. If this fails, please replace the 10 normally closed electromagnetic valves. If this still does not work, please change the gear pump.6, if A 7)electromagnetic coil magnetic won’t rise, need to open the pet-name ruby two four-way valve and attending normally closed electromagnetic valve removed entirely, wash valve holes and mesh with diesel or gasoline, remounted after cleaning, to start the test again, if still can’t normal rise out of the oil, then you need to replace pet-name ruby two four-way valve, replace or not rise after the oil, the attending normally closed electromagnetic valve replacement after, if the valve is replaced, or not to give oil, does not rise, the need to replace the gear pump;

(2)There is no going down or oil discharge.

- If the motor does not work properly when pressing the DN button, please check if the circuit is properly connected according to the paradigm. Please check if the power supply is connected correctly or if there is electricity in the electromagnetic oil.

If the motor works properly, but the oil would not return or the hydraulic cylinder goes down, please check if the indicator light of the 8 electromagnetic coil B is lit or not. If the light is off, please check if there is something wrong with circuit connection or switch status. Please note that the indicator light of 8 electromagnetic coil B must be lit if there is magnetic force and the motor is working simultaneously. - If the motor starts normally and the indicator light of 8 electromagnetic coil B is on, but there still is no oil returning or hydraulic cylinder descending, please check if there is magnetic force within the 8 electromagnetic coil B. Please take it off and insert the screwdriver inside the coil to check it with the DN button on. Please check if there is a magnetic force or suction force when the light is lit and change the 8 electromagnetic coil B if needed.

- If turning on the Down button, the motor functions properly, the indicator light of 8 electromagnetic coil B is lit and there is no magnetic suction force, and there is no descending cylinder or returning oil, then please dismantle the 10 normally closed electromagnetic valve and clean off foreign materials attached to it. Please blow it under a high-pressure air pump after cleaning. Then reload them to see if it works properly. If it still fails, please replace the 10 normally closed electromagnetic valves. If it still fails, please replace the gear pump or check if the model of

the pump is correct or not.

(3)Automatic downward movement at the end of rising.

Suppose oil drains back and the hydraulic cylinder goes down automatically without pressing any button at the end of the rising process. In that case, one should first dismantle 10 normally closed solenoid valves to clean up foreign materials. It may also be caused by wrongful connection. Please check the connection directions of the oil return and outlet ports. Once it is properly cleaned or correctly connected, this problem will be solved.

Technical Parameters

| Name | ParameterName | Unit |

| Traffic | 1.1 | Mi/r |

| Pressure | 22 | MPa |

| Rotating Speed | 2850 | r/min |

| Power | 1.6 | KW |

| Voltage | DC12V | V |

| Reservoir | 4-12 | L |

Operation Method

- Please connect the hydraulic power unit with the reservoir using clean oil pipelines.

- Please connect the motor with the electromagnetic valve in a proper manner. And ensure that they allow the same kind of current(alternative or direct)and the same voltage.

- Please turn on the motor to observe if there is anything abnormal.

Turn on the motor without loading actuators to do a dry-running and check if all the parts are running smoothly. If everything is OK, then load them step by step till they function normally.

Caution

- The system pressure of our hydraulic power units has been set prior to their shipment. You could adjust system pressure by adjusting the press to regulate the valve according to your needs, but the pressure should never exceed the nominal pressure of the system.

- Please carefully check if the motor and the electromagnetic valve are properly connected. Virtual connection is prohibited.

- The reservoir shall maintain an adequate load of oil during the initial installation and trial run. The reservoirs shall be replenished at the end of a work circle, but it shall not be overly filled.

- While connecting electromagnetic valves to the motor, it should be carefully checked to ensure that the nature(direct or alternative current )and voltage of the power supply are the same as labeled. The motor housing with ÄC power supply must be soundly grounded. It is prohibited to turn on the motor should it not be grounded. The junction box of the motor should be waterproof and moisture-tight. During the first time of connection, the direction of the motor should be carefully checked. Looking for the rear end of the motor, the motor should be turned on anti-clock wisely. It is absolutely prohibited to let the motor run adversely or to race without oil.

- The hydraulic oil to be filled into the reservoir should be filtered and the filter precision should be no less than 25μm.

- The power unit could not filter foreign materials within the hydraulic cylinder, therefore, the interior of the hydraulic cylinder must be kept clean to prevent the ill-function of the control valve. And the pipelines should also be kept clean.

Maintenance

- Actuators and pipelines should be kept clean to prevent the introduction of foreign material into the system.

- The reservoir should be adequately filled with oil.Proper refiling is needed after certain working circles. It may damage the oil pump and the enclosure if the oil pump sucks air.

- The hydraulic oil should be replaced upon working for 100 hours since the initial filling. Subsequently, the hydraulic oil should be replaced once per year/about 1500 working hours.

- The viscosity of the hydraulic oil should be 22-46mm2/s.

- High-viscosity hydraulic oil should be used in high temperature working environment while low-viscosity hydraulic oil should be used in low temperature environment.

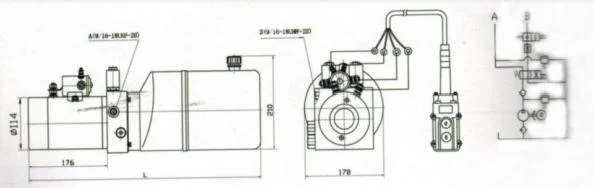

Schematic Diagram