Have you spent a lot of time searching for a quality hammer? Or you have been a jeweller or metalsmith for a long time and looking for a horn, hard and heel anvil to open doors in expanding your work. Your anvil should be as hard as a pocket knife. Is that something you’re having? VEVOR steel anvil makes the blacksmith’s work easier without having to sit low and bolt down while working. Due to ignorance, anvils are made up of soft steel.

With 132 lbs, this anvil provides a comfortable and wide work surface that allows you to work on a large area. Get a long time thumping with a wide and flat surface for a more convenient use experience. Its flat horn lets you in the tight spots that normal anvil can’t allow. This review guide will allow you to understand the real facts about the VEVOR anvil and how this anvil can be a bed rocking for your knife-making journey.

Understanding VEVOR Anvil

Look at your anvil and ask yourself if it is the best one you’re having so you’ll know the best time to upgrade it. A large block of hardened metal forged and steel casting with a flat surface- the VEVOR anvil makes your work efficiency high with no vibrations while working.

It is a perfect treat for jewellers, metalsmiths, handymen and hobbyists to make forging, forming and riveting metal. Comes in different weights but their prices are not more than your car.

VEVOR Anvil Reviews

If you’re looking for a flat and round anvil simultaneously that doesn’t sway in the middle of the work, you’re at the right place. This round and flat horn VEVOR anvil blacksmith is used for multiple projects whether you want to bend, shape or smooth. So, you can spend less than 20+ hours in regrinding it. In punching and twisting, it shows you a good performance.

It comes with a warranty and doesn’t need much care as this blacksmith is corrosion-proof and durable. Furthermore, the oxidation reaction will be relieved through spray coating.

Specifications

● Height: 215mm

● Length: 670mm

● Width: 155mm

● Color: Blue

● Hardy Hole: 27 x 27 mm

● Hardness: 50 HRC

Pros

● Round Hole: 27 mm

● Polishing Treatment

● 2 different holes and horns

● Forged Steel Construction

● Large and Wide Countertops

● Good Edges

● Able to Put Crisp Lines on Your Knife

● Stable & Solid Design

Testing VEVOR Anvil

Let’s take a look at how this extraordinary VEVOR anvil works. You’ll learn step-by-step process to make your new custom beautiful knife.

Step 1: First, place the blade in the chimney and remove it when it gets hot.

Step 2: With the help of an anvil and hammer, forge the blade. To give your favorite custom shape, repeat this process several times.

Step 3: You’ll need to heat your blade occasionally when it gets cold. As you can see in the picture, the bending blade gets a straight shape when you forge it many times.

Step 4: Now, the blade has changed its shape. Hammering it from every corner for balancing.

Step 5: Hammering the knife from the handle and give it a flat shape.

Place the knife in a manual bench vise and start hammering the knife. See how successfully the knife is holding your knife. So, you don’t need to grip a knife with your hand.

Step 6: Place your knife on a roundy horn and give the shape by hammering. The forging process contains steps and steps.

After giving the desirable shape to your knife, clean the countertop with a cloth.

You can see the knife has changed its shape. Additionally, you require higher skills to properly accomplish this frogging task.

Step 7: It’s time to grind the forged blade with the help of a grinding machine. Do the grinding process from every side.

Move your knife upward, downward, left and right. By doing this, you’ll successfully complete this process.

Step 8: Your knife is in good shape with a sharp edge.

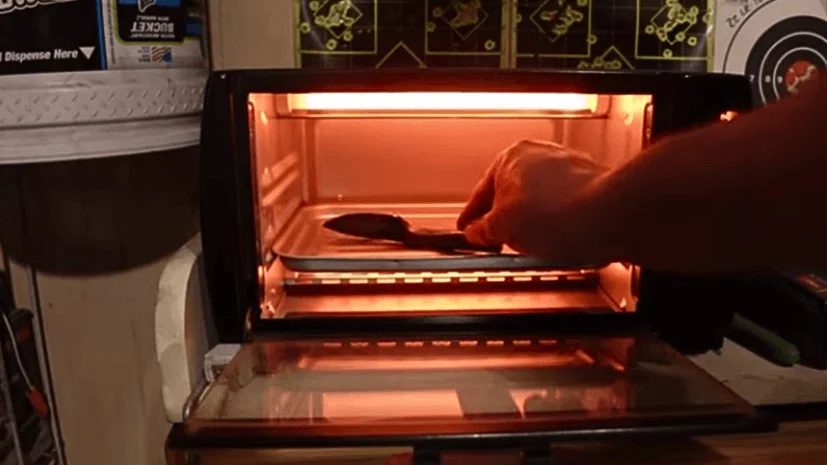

When you finish grinding, place the knife in a burner and take it out after the heat treatment process.

Step 9: Preheat your oven and start tempering the knife. After this process, let your knife cool to room temperature.

Additionally, if you still see the edges are sharp, then again, grind it. Make sure every side is even. To make a hole, sand down it until you see a sharp line. Drill the pin holes and clamp the blade; do it with the drill machine if you have any.

FAQs about VEVOR Anvil

1. How can you tell a good anvil?

It’s a good idea to have your anvil at least 50 times heavier than what you’re striking with. You need a 10-60kg anvil using a 1kg hammer to forge blades.

2. How long does an anvil last?

The average anvil will last you about 25 uses, but it can last much longer or less, depending on your luck.

3. How long do anvils last?

Each time an anvil is used, it has a 12% chance of getting damaged – chipped, broken, then destroyed.

4. How do anvils hold up so well?

Having sharp edges also causes cracks to form in the metal being worked. The anvil face is hardened and tempered to resist hammer blows so it won’t bend.

5. Old VEVOR anvils are worth anything?

An anvil is a great investment. The value of an investment increases over time. Also, VEVOR anvil get more valuable as they get older and in better shape. You get better at blacksmithing, and their value goes up.

Conclusion

With a tight budget and a quality product, the VEVOR anvil has remarkable features and excellent customer reviews. Nowadays, anvil prices have skyrocketed, but this VEVOR anvil is just $259 with a wider and larger countertop to work on. This tool is the best option for startups that want quick shipping and don’t want to spend months on it.

A worthwhile tool for a metalsmith…