Is making a smooth, clean, quick metal cutting your new project requirement? Then to save yourself from rough cutting, noisy grinding, imperfect shaping, and a filthy workplace, you just need to buy a plasma cutter. Welding with plasma is similar to plasma cutting.

But the main thing is that a plasma cutter uses a higher temperature level to slice through electrically conducting materials, so rather than fusing the metal, it breaks it down. A great technique to cut many metals without distraction, abrasion, and silvering associated with traditional cutting techniques.

It may be difficult to choose the best manufacturing company since so many of them exist. But now there’s no need to go here and there because the VEVOR plasma cutter 50A HF helps you to achieve clean and smooth cuts throughout the project on a wide range of materials. It just looks like a torch-cutting tool. It’s not a boon for professionals, but beginners can also take help from this.

Understanding the Pilot Arc Technology

By ionizing the plasma gas, the spark creates a low-resistance path for current to flow between the electrode and nozzle. There is a flow of energy and discharge between the two components through the pilot arc.

The letter P on the device denotes the pilot arc. Because of their extra wire, you can identify the pile arc. High-frequency wires have the same hookup. This wondrous machine has an air intake valve, and the gauge is positioned at the back rather than the front. To be ready to plug the VEVOR 220-volt plug machine is the best investment you would make.

VEVOR Pilot Arc Air Plasma Cutter Reviews

Do you want a smooth cut like butter through three-sixteenths of metal? Buy a VEVOR Non-Touch Pilot Arc Plasma Cutter. It’ll still look like a brand-new cutter and barely even touch after the first use. To check out its speed, you can cut faster, and you’ll notice it’s still efficient at this speed. But keep in mind that you need cleaner ground for the VEVOR pilot arc for your eight-gauge metal. First, clean it and then start work on it.

Now you can glide through the metal effortlessly, just like butter. To make a masterpiece, it works great with eight-inch and three-sixteenth-inch cuts.

Right now, it’s time to check a quarter-inch-thick ranch; how well it handles our work. With good ground, see how easily it slices through the quarter-inch metal. Undoubtedly, this machine is superior as it works and works well on the quarter-inch ranch too.

But to ensure its quality, let’s see how it’ll work on eleven-sixteenths thick metal; unfortunately, this machine can’t work out well on 11/16 as it’s too thick to handle. But let’s again try cutting with a quarter-inch thickness. Is it still working on it or not?

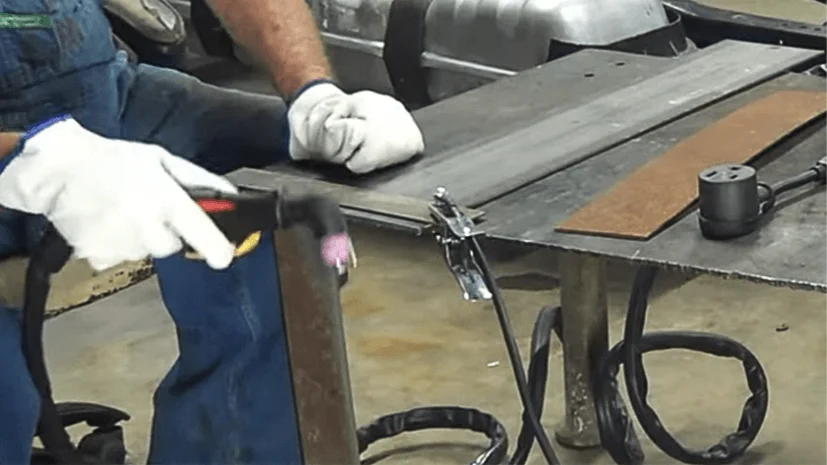

As in the picture, you can see through a quarter-ranch; it cuts like butter. Surely, it’ll also work great on a clean piece of half-inch metal. However, there’s no need to work on rat rods as there’s no plan to cut through the quarter-inch metal.

You can see the VEVOR Pilot Arc Plasma Cutter Capability through the quarter-inch metal. Also, with the 30-gauge sheet metal, you can see it slice through conveniently. By leaving a clean cut on sheet metal, you can work quickly and accurately.

With minimal slag, the result of cuts of three-sixteenth metal will come out calmly. On various thicknesses, this machine performs well. Though we don’t have quarter-and-half-inch metal right now, cutting through these metals will be relatively easy.

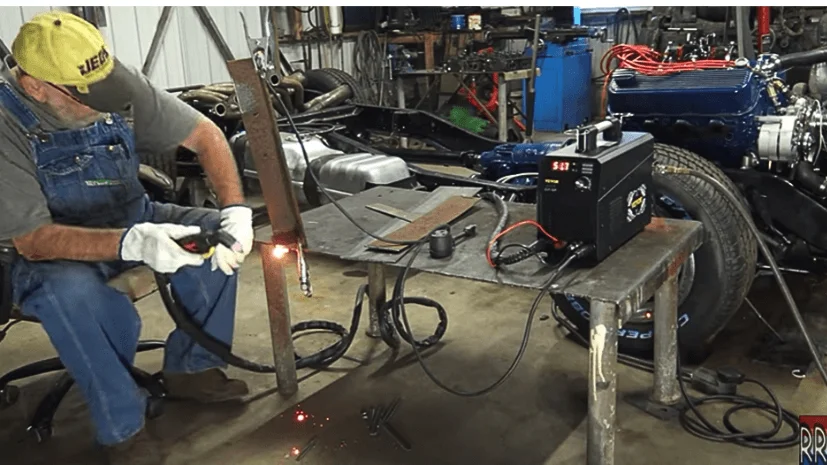

Actually, the purpose of this investment is not to cut the half-inch metal, but if we use it to cut half-inch metal, it works out well and handles the task well. Basically, the main purpose is to cut three-sixteenths an inch and even a smaller one. So up to 10-guage. While building a rat rod, you can perfectly cut eight and three-sixteenths inch material. Beyond doubt, it shows impressive work for old, corroded metal for building a battery box for C10.

How to Use the VEVOR Pilot Arc Air Plasma Cutter

Let’s power up a machine. Try to run it fully and connect it to two power sources. The green light indications mean you’ve started it out, and the yellow light will blink when it shows as a warning. Do you know? This machine has a 30% duty cycle, so it will automatically shut off if it overheats due to excess use. As a precautionary measure, it’s recommended to cut it in short intervals and allow it to cool for some time. By pulling the trigger, the pilot arc is easily initiated.

You can get advantages from this product due to two reasons. First, if you’ve got a CNC table, connect this machine to it, and then you can change the machine’s head. Furthermore, the tip does not have to be in direct contact with the metal when cutting, thus extending its life.

Is the VEVOR Cut 50P Worth the Investment?

Yes, it’s a valuable investment as this plasma cutter has dual-voltage 110/220V with an adapter. A great device that can effortlessly attach with welders and generators. Additionally, it can easily store your bulky cables and power cable with the provided two cable racks. To make it easy to carry, it comes with a comfortable handle with its lightweight 22 lbs/9.8 kg.

Now those who’re beginners and don’t know much about the Pilot Arc technology, then this VEVOR Pilot Arc Air Plasma Technology Cutter waterproof and dustproof feature stands out in the market. For your most challenging DIY project, you can rely on VEVOR.

FAQ About VEVOR Pilot Arc Air Plasma Cutter

1-In plasma cutting, what is a pilot arc?

In plasma torches, a pilot arc is an arc that does not transfer from the electrode to the nozzle. During the pilot arc, the orifice gas (plasma) is excited into plasma.

2- How does the pilot arc function?

Using the Pilot Arc technology, a spark can be generated at the tip of the torch without ever touching the material itself. The Pilot Arc system has the advantage of igniting the spark several inches away from the cutting surface of the torch.

3- What are the methods for starting a plasma arc cutting arc?

An arc can be initiated either through a high-frequency pilot arc, a touching arc, or a back-blow arc. During the start of a touch arc, the plasma nozzle must contact the workpiece to initiate the arc, while during a pilot arc, the plasma nozzle already contains an arc, and no contact is required.

4- Can you explain what a non-touch pilot arc plasma cutter is?

A torch using pilot arcs can cut through unfinished, painted, and corroded surfaces with minimal slag production. The metal tip is not touched during the cutting process using pilot arc technology.

Bottom Line

So, you read out how the plasma cutter work. They usually sell like hotcakes and usually get out of stock, but they’re stocked up within a week or two due to the customer’s huge demand. So don’t wait long if you need one, as you’ll never get this type of pilot arc air plasma cutter 50A at such a price. Browse VEVOR and see what they’re having for you right now!