In creating a beautiful, sleek blade, the belt grinder makes a huge difference whether you’re an expert or starting your journey into knife making. It can be challenging to decide what belt for grinder you should choose in the knife-making process.

But before selecting the belt grinder for knife sharpening, you must consider different factors, as belt grinders may look similar. However, specs and features can vary, resulting in unique performance. So, in this article, you’ll learn what you should consider when buying a belt grinder for knife sharpening.

The Crucial Role of a Belt Grinder in Knife Sharpening

A belt grinder is also called a bench grinder. If we compare a belt grinder vs. a belt sander, the belt grinder is useful in shaping and grinding the metal. Also, you can use belt grinders for polishing the surfaces and giving a metal a concave finish.

Here are some key distinctions why belt grinders differ from other sharpening tools:

- Versatility: A belt grinder for knife sharpening is highly versatile and beyond sharpening and is used for many tasks: shaping, grinding, and polishing.

- Other sharpening tools: They’re often designed for sharpening particular tools and don’t have additional functions like blade grinding.

- Speed & Efficiency: Quickly sharpening the tools and faster in material removal. Through continuous motion, the grinding belt allows efficient stock removal.

- Other Sharpening tools: Require more time and efficiency in removing the materials.

- Precision: Offer precision when equipped with a suitable grind belt and used with care.

- Other Sharpening tools: Whetstones provide minimal control over sharpening.

- Portability: According to size and design, the belt grinder for knife sharpening is portable compared to other sharpening tools.

- Other Sharpening tools: They’re less portable in size and design and more accessible.

Features to Look for in a Belt Grinder for Knife Sharpening

You should consider several features when selecting a belt grinder for sharpening knives. Some of them are the following:

Belt size and Compatibility

Make sure the grinder can accommodate belts of the right size and compatibility. For various sharpening stages, belts of different grits and types are used. The most popular size of the belt grinder is 2×72 mm.

Adjustable Speed

You can control the grinding speed with a belt grinder with variable speed settings. Depending on the blade type and material, different speeds are needed. If you’re working on wood, then speed is slower than working on the metal. In surface per minute, speed is measured. The grinder belt for knife sharpening is required to be between 4100-7000. However, for knives, the optimal belt speed rotation is 300-400 m/min. But it all depends on the metal type you’re working with.

Grit Options

If you’re sharpening knives with a belt grinder, having different grit options makes the process more efficient. Typical belt grinder grits and their uses:

- Medium Grits: Often, it is used for reshaping blades and removing material quickly. It is ideal to use coarse grits to quickly repair damaged or dull edges. In sharpening, they are often the first step.

- Fine Grits: Fine grit belts are used for further refinement. Removing scratches left by medium grits results in a smoother, sharper edge. A polished finish requires fine grits.

- Flexible Belts: Some belt grinder knife sharpeners offer flexible belts to conform to the shape of the blade. These belts are used in tasks requiring precision for the blade’s irregular shapes and curved sharpening.

- Coarse Grits: Using this tool, rapid material removal and reshaping can be possible. For damaging repairs and dull edges, coarse grits are ideal.

Grit sequences should be selected based on the knife condition, steel type, and personal preferences. A controlled and effective sharpening process starts with coarse grit and progresses to finer grits.

Step-by-Step Guide: Knife Sharpening with a Belt Grinder

Firstly, you need to choose the right grinder for knife sharpening. So, choosing the right grit is an essential part of this process. You should consider a 50-grit if you have the toughest material, such as carbon steel. To sharpen a knife, take a look at the following steps:

- Clean your knife with a rag; to do this process, gently polish the knife with an oily rag and remove the dirt and rust.

- Now, look at how many sharp edges your knife has because some knives have two sharp edges while some have one flat edge and one sharp edge.

- Make sure your grinder belt isn’t too tight or too loose because it could ruin your blade.

- Now, start running the grinder and apply pressure up and down the length of the disk or belt. Start flipping the blade if it’s double-sided. If you’re honing your skills, put one hand on the hilt and one on the blade tip to exert maximum control.

- After achieving your desired sharpness, let the blade cool. Since grinding generates much heat, you should cool your steel in water. Water will prevent the blade from damage and cool it immediately.

Once you’re satisfied with the work, use sandpaper to create the more smooth and sharp edge. Now, check the blade’s sharpness. Place the blade on a sheet of paper’s top edge. If your blade cuts paper quickly, it is sharp enough. Wipe your blade down before using it in the future, and store it in a dry place.

Benefits of Investing in a Quality Belt Grinder for Knife Sharpening

You can get numerous benefits if investing in a quality belt grinder for knife sharpening as they not only involve precision, efficiency, and overall satisfaction for the sharpening process but also have a high upfront cost and long-term investment advantages for professionals and beginners who are into knife sharpening business and other related tasks. The following example shows the importance of precision in knife maintenance:

- Sharpness and Cutting Performance: It’s important to keep knives sharp to get the best cutting performance. Sharp edges make clean, precise cuts, reducing the effort required for food preparation.

- Edge Retention: Edge retention is improved with precision sharpening and honing. When an edge is precisely honed, it lasts longer before it needs to be re-sharpened, saving time and effort.

- Safety: Well-maintained knives have an edge that is precisely honed. A dull knife is more prone to slipping, resulting in an accident.

- Consistent: Consistent and uniform cuts come from knife maintenance. It’s crucial in professional kitchens where presentation and portion control are key.

- Minimize Material Loss: Precision sharpened knives lose little material during cutting.

- Professional Appearance: The appearance of food is important in culinary and professional settings. Knives in good condition contribute to a professional presentation, whether using them in a home dinner or a restaurant kitchen.

- Time Efficiency: Preparing food with a precisely maintained knife is quicker and more efficient. Using an imprecisely maintained or dull knife saves time and improves kitchen efficiency.

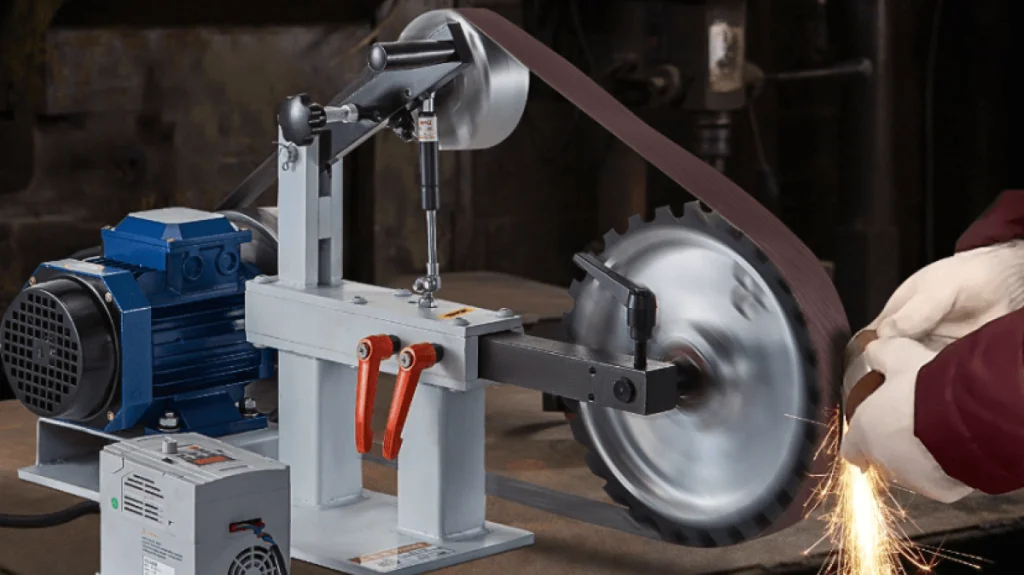

Elevate Your Knife Sharpening Experience with VEVOR’s Belt Grinder

VEVOR belt grinders are made of high-quality stainless steel for precision, durability, and longevity. Various options are available for you to choose from. The belt grinder and senders are built in at the same time. With their high-abrasive belt and durable wheels, these 3-in-1 Vevor belt grinders provide a non-slip design and fast grinding speed. Precision plates are made from high-quality materials to ensure accuracy. It enhances comfort while using and is available in different sizes.

Despite buying different types of grinders, VEVOR lets you do circular, flat, and arc grinding with just one arm. Meet your work requirements for grinding metals, acrylics, wood, etc. A wide range of applications include polishing and building materials. Speed can be converted from phase 1 to phase 3 using a frequency converter.

Features:

- Durable Construction

- Easy Operation

- Wide Application

- Adjustable Speed

Conclusion

To grind wood, metal, or concrete, a belt grinder- an electromechanical tool is used. However, you can quickly remove the old paintwork from the metal through belt grinders. You can grind any surface and perform primary and secondary grinding with a VEVOR belt grinder. When you’re looking for a belt grinder that won’t break the bank and offers a 3-in-1 function, go for a VEVOR belt grinder that provides precision and speed while working. Get your product at your doorstep with no hidden charges.