Introduction

Can’t you get a clue about HEPA filter construction? If your house or work station is full of dust particles, allergens and pollutants, don’t worry. Fret not. In “HEPA Filter Construction Guide” you will discover details of these important devices. Get buckled up and find out the mysteries of their mechanism and functionality. From multi-level filtration to the capture of particles science, this guide gives you the needed knowledge. Say goodbye to airborne irritants with no hesitation. Discover how HEPA filters operate and how this technology could empower you to make choices that contribute to cleaner and safer surroundings. Let’s dive right in.

Table of contents

Components that Facilitate HEPA Filter Construction

The main building blocks that make up HEPA filter construction are:

I. Filter Media

Two primary types of filter media go into the HEPA filter including fiberglass and synthetic polymers.

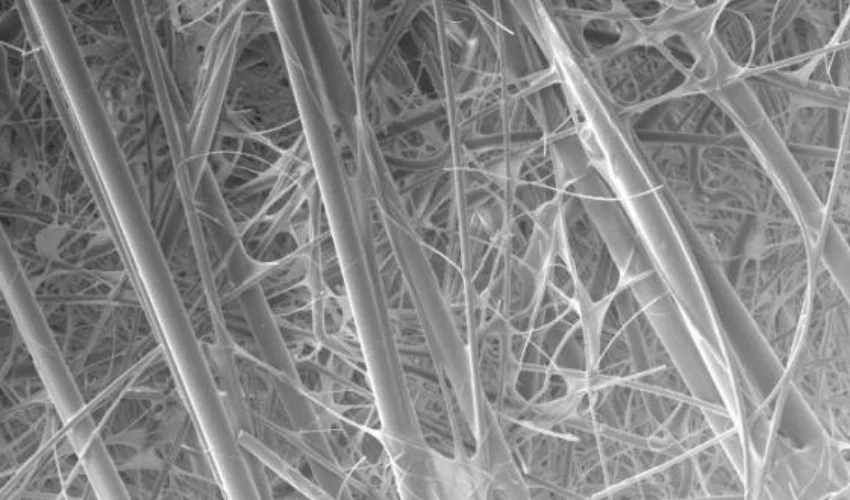

A. Fiberglass

This design comprises myriad pieces of fibers with no uniformity. The randomness of the fibers provides that particles have a great chance to get hooked, which facilitates filtration efficiency.

B. Synthetic Polymers

Different than the fibrous glass, the synthetic polymer fibers are positively charged. As this electrostatic charge attracts particles like a magnet, it enhances filtration effectiveness. The extra electrostatic charge on the filter adds to its effectiveness in capturing smaller particles, thus resulting in cleaner airflow.

II.Frame

The box of a HEPA filter offers essential support and structural strength to the filter material. It comes in a variety of materials and designs.

A. Material

HEPA filter frames are often built from rigid materials such as cardboard, aluminum, or plastic. These materials ensure durability and strength.

B. Design

The HEPA filter frames may come with different configurations such as mini-pleat or V-bank design. Each design will have distinctive advantages in the airflow and the structural stability.

The frame guides the filter media into place, sustaining its integrity and utility in operation.

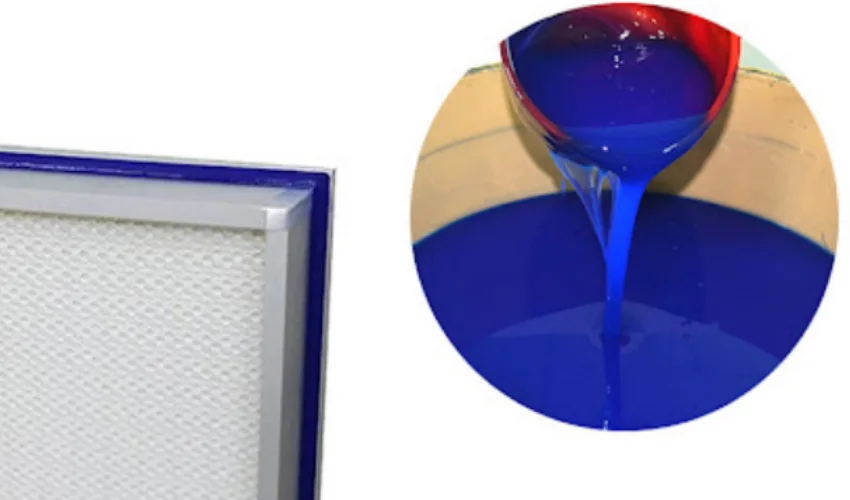

III.Sealants

A. Adhesives

The adhesives would be used to adhere the filter media to the frame tightly. As a result, adhesives seal the gaps between the filter media and the frame which blocks bypassed air flow.

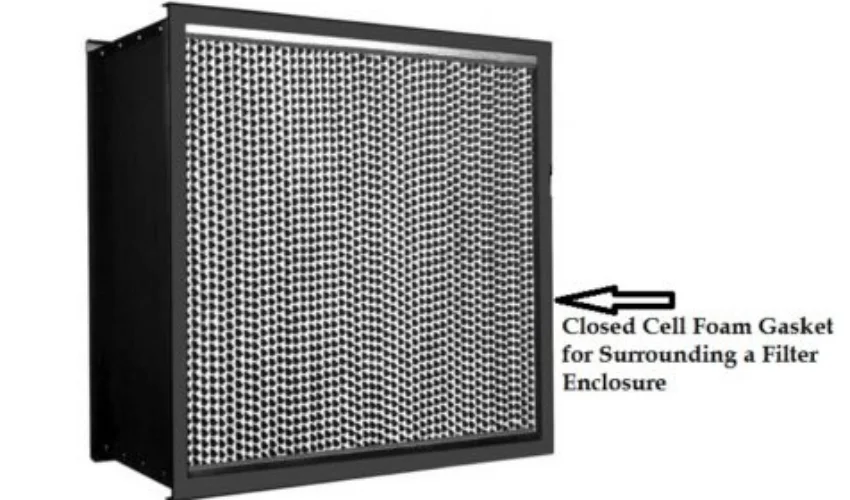

B. Gaskets

Gaskets are commonly made of rubber or foam and are positioned around the edges of the filter to create a tight barrier. Once the filter is installed, the gaskets compress against the housing creating an air-tight barrier that stops air leaking before it can be filtered.

IV.Support Grid

A. Material

Support grids are usually constructed with lightweight but robust components like aluminum or steel.

B. Grid Pattern

The grid reinforces the filter media, defending it from collapsing under airflow pressure. Thus, the support grid averages out the pressure applied to the filter media so that the structure stays intact for a long time. Read this if you are wondering how long HEPA filter last.

V. Pleating

A. Arrangement

Folding back the filter media, and pleating generates a bigger surface area, which allows more particles to get caught.

B. Purpose

The high surface area offered by pleating enables the filter to deal with smaller particles and not obstruct the airflow. Even though pleating enlarges the surface area, the resistance to the flow remains low, which provides for the effective circulation of air.

VI.Housing

The manifold of a filter housing keeps the filter assembly enclosed, providing protection and ease of installation.

A. Enclosure

The filter media, support grid, and frame are all contained in the housing, keeping them firmly in place. Certain housings have access panels or latches, fitted to make it simple to fit, look at or change the filter.

VII.Gasketing Material

A. Additional sealing material

Gasketing material is positioned at the edges of the filter and provides a tighter fit between the filter and housing.

B. Purpose

Sealing with the gasket material will reject the dirty air which is not filtered. A secure seal guarantees that all the air flowing into the filter is properly filtered limiting efficiency wastage.

VIII.Anti-Microbial Coating (Optional)

A. Treatment

The antimicrobial coating is incorporated into the filter media at the manufacturing stage.

B. Purpose

The coating does this by blocking bacterial, mold, and other microorganism growth thus maintaining filter cleanliness and hygiene. A cleaner filter reduces air pollution and extends the filter life simultaneously.

Stepwise Process of HEPA Filter Construction

Get insights on the stepwise procedure of HEPA filter construction:

I. Preparation Stage

A. Selection of Filtration Media

Go for materials such as fiberglass, microglass, and synthetic fibers which are well-known to be highly efficient in capturing particles

B. Cutting Filter Media to the Required Size

After choosing the filter media for HEPA filter construction, you will need to cut it to the right size. Measure correctly and use a sharp knife to achieve uniform cuts without creating any irregularity.

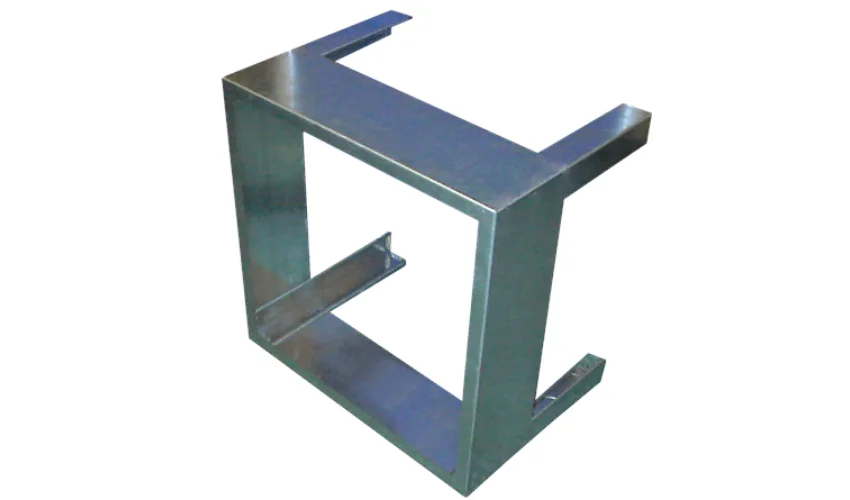

II. Frame Fabrication

A. Frame Material Selection

Take into account aluminum or galvanized steel which is corrosion resistant as an option for the frame. The frame serves not only as structural support to the filter but also gives a tight seal during installation.

B. Cutting and Shaping The Frame

Cut the frame material according to the size of the media filter. Make it so that it fits exactly with the filter media. So, that no gaps are left that can lead unfiltered air into the filtration system.

C. The Assembly of Frame Components

Do not forget to secure the frame components properly by welding and/or riveting. Make sure the frame is rigid and steady in order to withstand the airflow pressure without deformation.

III. Adhesive Application

A. Application of Adhesive

Pick out an adhesive that can be used as an evenly applied coat along the frame’s edges. Select adhesives that are compatible with both the frame material and the filter media.

B. Evenly Distribution of the Adhesive

Spread out the adhesive evenly in order to avoid lumps or gaps. An even distribution of the adhesive layer guarantees the effective fitting of the filter media to the frame in HEPA filter construction.

IV. Placement of Filter Media

A. Proper Positioning to the Frame

Attach the cut filter medium to the frame without leaving any gaps, ensuring it is perfectly aligned and covers the entire surface area. Take care to prevent the filter media from getting torn or creased.

B. Pressing tightly onto sticky tape.

Press the filter media strongly onto the adhesive so that the contact of the media and the frame are complete. Apply consistent pressure to press the filter media downwards, and at the same time, improve the sealing effect.

V. Sealant Application

A. Using Sealant on Edges

Make a bead of sealant around the filter media edges where it meets the frame. This supplementary sealing not only blocks air leakage but also ensures that all conditioned air passes through the filtration media.

B. Utilizing Gaskets or Foam Strips for improved sealing.

In order to achieve better sealing in HEPA filter construction, you may think of adding gaskets or foam strips between the filter and the frame. These materials fill up any remaining holes, thus making an airtight sea.

VI. Support Grid Integration

A. Support Plate over the Filter Media.

Put the support grid above the filter media and make sure that it lies uniformly across the surface. This grid acts as a framework for the filter and prevents the media from collapsing under the pressure of an airflow.

B. Maintaining Proper and Stable Sealing

Fix the support grid permanently to avoid its displacement or misalignment during operation process. Good placement guarantees uniform airflow distribution along the filter material.

VII. Final Inspection

A. Visual Inspection for Defects

Carry out a detailed visual examination of the assembled filter for any defects or non-uniformities. Take a look for tears, wrinkles, or misalignments that could impact filtration performance.

B. Evaluating Integrity of Seal and Structural Soundness

Check the integrity of the seal by applying light force to different parts around the filter borders. The stable and rigid frame gives the impression that the assembly and sealing have been carried out properly.

VIII. Quality Control Testing

A. DOP or PAO (Leak Testing)

Test for leaks in HEPA filter construction using either Di-Octyl Phthalate (DOP) or Poly Alpha Olefin (PAO) aerosol challenge. This test confirms that the filter captures the particles without letting any of it leak.

B. Airflow Resistance Testing

Maintain the airflow resistance through the filter at an acceptable level. High resistance may lead to decreased performance of the system and higher energy consumption.

C. Efficiency Testing

Carry out efficiency testing to see if the filter can filter particles of a certain size. Make sure the filter complies with or goes beyond the efficiency standard for its particular application.

IX. Packaging and Distribution

A. Secure Packaging

Securely package each filter to prevent it from being damaged during movement and storage. Use strong materials and ensure your cushions do not deform or get punctured.

B. Labeling Each Filter

Label each filter with vital information such as the model number, efficiency rating as well as installation instructions.

C. Distribution to customers or installation.

Lastly, package the filters and deliver them to clients or install them into HVAC systems based on project specifications.

Factors Influencing The Choice of Right HEPA Filter

Uncover the key factors that impact the choice of the right HEPA filter construction below:

Airflow Requirements:

Calculate the airflow rate you need for your area. To avoid insufficient filtration and circulation, a HEPA filter of adequate airflow capacity is the best choice.

Application Requirements:

Choosing the right HEPA filter depends on the requirements of your application. Do you want to improve the air quality in a hospital, a lab, or a residence? By personalizing your selection to your environment one guarantees peak performance and success.

Particle Size and Filtration Efficiency:

Evaluate the particle size for which you require filtration and the level of filtration efficiency necessary. HEPA filters are of varied capability which allows them to capture particles of different sizes. This is why it is necessary to determine your needs so that you can effectively purify air.

Physical Dimensions and Compatibility:

Take into account the physical dimensions and suitability of the HEPA filter for your air filtration system. Proper fit and compatibility ensure a hassle-free installation process and optimal functionality.

Construction Materials and Durability:

Assess the construction materials and life span of the HEPA filter. The use of quality materials as well as a reliable configuration result in extended lifespan and less repair costs in the long-term.

Sealing and Gasketing:

Be mindful of HEPA filter sealing and gasketing mechanisms. Through appropriate sealing, the possibility of air leakage is eliminated and the efficiency of filtration is increased, which in return keeps the environment in pristine condition

Top HEPA Filter Products to Elevate Your Indoor Air Quality!

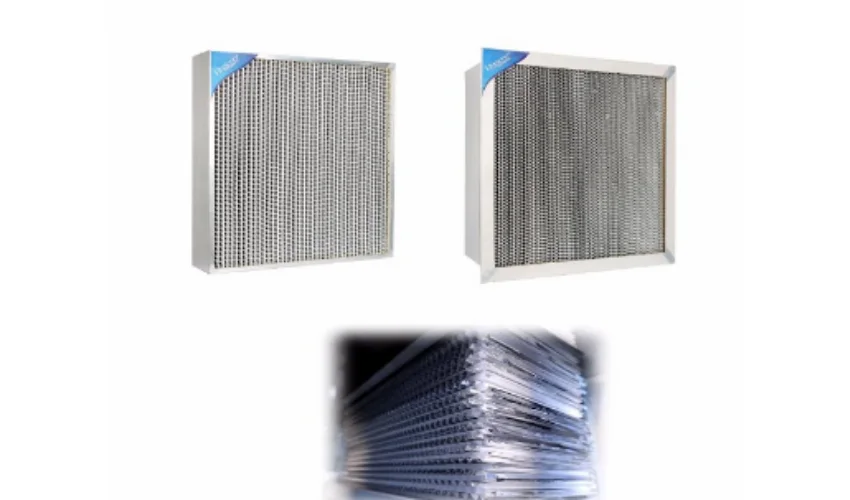

VEVOR HEPA Filt

Upgrade your air filtration system using the VEVOR HEPA Replacement Filter. This 24”x24”x11.5” AC Filter has true HEPA technology, which traps 99.97% of particles down to 0.3 microns in size. The galvanized frame that distinguishes it provides for its endurance and resistance to deformation better than the conventional filters. The deep-pleat design and fiberglass cotton construction combined together help the filter perform well for cleaner air. Proper sealing and big debris size capacity make it long-lasting while its versatile application fits both residential and commercial situations. Bid farewell to contaminants and breathe in fresh sterilized air with this reliable HEPA filter replacement.

VEVOR HEPA AIR Filter

Improve air purification with VEVOR HEPA Air Filter replacements. The package for this 15.75” x 15.75” x 0.75” consists of five filters with high efficiency, filtering particles of 0.3 microns down to 99.97%. Protect your space from allergens and pathogens efficiently. Just snap them in the BlueDri or VEVOR 3- 3-stage filter for a powerful filtration system. These air masks are designed to ensure no leaks for a cleaner, steady supply of air. Forget about the installation hassle and take time for regular maintenance to get the best service out of it.

FAQs

What is the structure of a HEPA filter?

The HEPA filter is made up of multiple layers of very fine fibers, which are randomly arranged. The fibers are generally crafted from materials such as fiberglass that form an intricate labyrinth. This design engages in trapping of small particles as the air passes through. The frame of the filter keeps everything in place and makes sure the filtration is efficient and leakage-free.

What is the airflow of HEPA filters?

HEPA filters are designed to maintain high airflow and at the same time capture the particles. The construction of the filter permits for maximum air movement to maintain efficiency in cleaning without blockage. This makes sure that filtered and clean air runs properly through the room.

What is the maximum pore size of a HEPA filter?

HEPA filters are widely known as the best ones in capturing even the smallest particles of 0.3 microns with the highest efficiency. This also includes allergens, dust, bacteria, and even viruses. The size of pores in a HEPA filter is highly important because they will determine what kind of particles will get through and what will be trapped in the filter’s fibers.

What is the distinctive feature of a HEPA filter and a filter?

The HEPA filters are simply outstanding in capturing ultrafine particles as against the regular filters. While traditional filters target bigger particles, HEPA filters provide more purification which enables them to retain smaller contaminants, meaning cleaner air for you to breathe. If interested know the differences between HEPA Vs True HEPA filter.

What is the HEPA filter thickness?

HEPA filters are available in various thicknesses that are dependent on the use and application. But, usually, their thickness is between 1 and 4 inches. This thickness is enough for the surface area requirement for filtration and also keeps the structural integrity and airflow efficiency.

Conclusion

Lastly, knowing the HEPA filter construction is paramount to clean air. You have come to know about the different layers and the way that it effectively traps particles. Now the time for action has come. Make sure you pick the right HEPA filter for your purpose. Do not skimp on air quality. VEVOR air filter products provide you with trustworthy options to protect your health. Take charge of your environment. Invest in cleaner air for you and your family. Choose wisely now. HEPA filters to purify indoor air. Allow VEVOR to help you select your perfect size. Breathe easier, and live healthier. Your health is literally in your hands.