Are you looking for a comprehensive guide on how to operate your VEVOR electric hoist safely and efficiently? Look no further! Our guide provides all the information you need to operate your electric hoist seamlessly.

From important safety precautions to troubleshooting, maintenance, and repair, our guide covers it all. Plus, we have included a PDF version of the VEVOR Electric Hoist Manual for your convenience. Keep reading to learn more!

Table of contents

Important Safeguards

| This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:( 1)This device may not cause harmful interference, and (2)this device must accept any interference received, including interference that may cause undesired operation. | |

| This symbol, placed before a safety comment, indicates a kind of precaution, warning, or danger. Ignoring this warning may lead to an accident. To reduce the risk of injury, fire, or electrocution, please always follow the recommendations shown below. | |

| This symbol, placed before a safety comment, indicates a kind of precaution, warning, or danger. Ignoring this warning may lead to an accident. To reduce the risk of injury, fire, or electrocution, please always follow the recommendation shown below. |

WARNING: Read all safety warnings, instructions, illustrations, and specifications provided with this machine. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious injury.

Basic Safety Information

- Please read the operation manual carefully before using the electric hoist.

- To Reduce the Risk of Electric Shock or Injury, Use Indoors Only.

- The installation position of the electric hoist must be selected at a place that meets the needs and is convenient for operation.

- Regularly check whether the hoist is firmly installed.

- Please do not overload and do not use the hoist when the weight of the lifted object is not clear.

- Do not operate hoist with twisted, kinked, or damaged wire rope. Inspect the wire rope carefully before every use.

- During lifting, it is not allowed to pull or lift heavy objects at an angle to avoid danger.

- Do not operate a damaged or malfunctioning hoist. Inspect the hoist carefully and test the operation before every use.

- Do not lift people or lift loads over people. Falling loads can injure or kill people.

- No one is allowed to stand under the lifting object when lifting the heavy object with the hoist.

- When operating the wire rope, please wear thickened gloves, and do not let the wire rope slip through your hand, to avoid slipping or stabbing.

- This electric hoist shall not carry people in any way or be used as an elevator lifting tool.

- The operator should not operate the electric hoist under the condition of drinking, taking medicine, or being ill.

- Do not modify or weld the parts of the electric hoist at will.

- When lifting the hoist, ensure that at least 3 coils of wire rope are retained on the rope barrel to prevent the wire rope from falling off the rope barrel due to excessive stress.

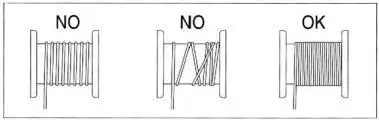

16. Before starting the work, make sure that the steel cable is correctly winded around the reel and that the pitch is equal to the cable diameter.

17. The warnings, precautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors that cannot be built into this product but must be supplied by the operator.

Product Parameters

| Model | WX440-1 | WX880-1 | WX1320-1 | WX2200-1 | YX440-1 | YX880-1 | YX1320-1 | YX1760-1 | YX2200-1 |

| Control Mode | Wireless Control | Wire Control | |||||||

| LoadCapacity /lb | 220/440 | 440/880 | 660/1320 | 1100/2200 | 220/440 | 440/880 | 660/1320 | 880/1760 | 1100/2200 |

| NetWeight /kg | 9.25 | 15 | 15.9 | 25.9 | 9.4 | 14.5 | 15.3 | 16.5 | 25.2 |

InputPower / W | 480 | 850 | 1150 | 1600 | 480 | 850 | 1150 | 1450 | 1600 |

| CableDiameter/ mm | 3 | 4 | 4 | 6 | 3 | 4 | 4 | 5 | 6 |

| Voltage | 120V/60Hz | ||||||||

| Lifting Height | 6/12 m | ||||||||

| Lifting Speed | 5/10 (m/min) | ||||||||

| WorkRate | 20% 10min | ||||||||

| Insulating Grade | B | ||||||||

Product Components

C. screw/gasket/ gasket ring(X4) | ||

E.sling 1 meter with ring(x1) | F.hook(x1)used in double linemode |

Installation Instructions

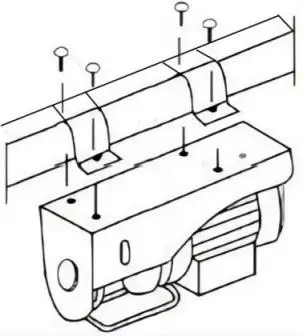

1. Install the electric hoist (A) on the beam with fixing rings (B) and screw/gasket/gasket ring (C), and pay attention to screw tightening.

Note: The installation position must be strong enough to support the load of the electric hoist during operation.

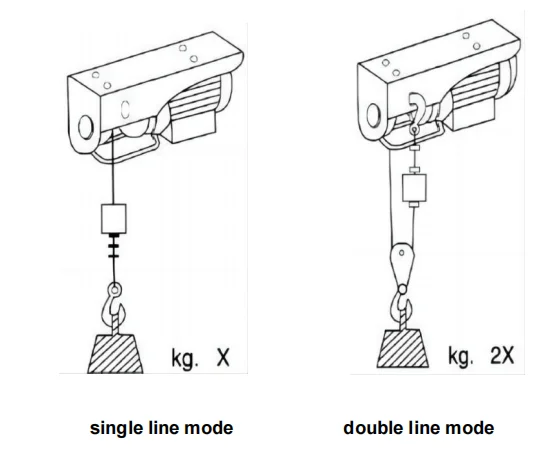

2. It can be installed into single-line mode or double-line mode as required. More load is available in double line mode but will need to be replaced with a new hook in the accessory pack (F).

3. Be sure to tear off the tape wrapped around the rope drum before the machine can be tested. If the machine is tested in a hurry, it may cause the wire rope to rewind and damage the limit frame.

WARNING: Gloves, safety helmets, and steel-toed work boots should be worn during installation and use.

Troubleshooting

Electric hoists after long-term use or improper operation may cause a variety of failures; common failure causes and elimination methods see the following table.

| Common Failure | Cause Analysis | Handling Suggestion | |

| 1 | 1. The power supply is disconnected. 2. The cable connection is broken or loose. 3. The switch is faulty. 4. Capacitor damage. 5. If the rise button fails, it may be that the limit frame is not reset or the switch is out of order. 6. The Emergency stop switch is not reset. | After pressing the remote control button to switch, the motor is noisy and can not start normally. | 1. The power supply voltage is too low. 2.Capacitor damage. 3. The remote control switch is in poor contact. |

| 2 | After pressing the remote controlbutton to switch, the motor is noisy and can not start normally. | 1. The power supply voltage is too low. 2. Capacitor damage. 3. The remote control switch is in poor contact. | Press the lift switch to make the hook drop to the bottom and the wire rope completely out of the rope barrel, and then start the normal work. |

| 3 | 1. The power supply voltage is too low. 2. Capacitor damage. 3. The remote control switch is in poor contact. | Please contact the sales unit or the company. | |

| 4 | Excessive noise during operation. | 1. Poor lubrication 2. Gear or bearing is damaged. 3. Poor assembly or parts are damaged. | Press the lift switch to make the hook drop to the bottom and the wire rope completely out of the rope barrel, and then start the normal work. |

| 5 | Electrification | The limit mechanism is faulty and the lifting instruction is contrary to the execution result. | 1. Poor Lubrication. 2. Gear or bearing is damaged. 3. Poor assembly or parts are damaged. |

| 6 | 1. The ground is faulty or ungrounded. 2. Ground the internal conductor with the housing. | Improper operation caused the wire rope to reverse wrap around the drum. | 1. Add grease. 2. Check and replace the gear or bearing. 3. Check whether the parts are properly assembled and repair the damaged parts. |

Maintenance and Repair

Maintenance

1. Check the screws fixing the electric hoist regularly.

2. Remove dust or corrosive liquid accumulated on the cable in time

3. The newly purchased electric hoist is filled with lubricating oil for lifetime maintenance. There may be a small amount of oozing when operating the miniature electric hoist, especially during the first operation. This is normal, do not need to refuel the electric hoist.

4. Check the wire rope regularly. If the wire rope is worn, replace it in time.

5. Repair or replacement of hoist components must be performed only by a qualified technician using only identical replacement parts with the same rating.

6. Note the following regarding specific components:

a. Replace damaged or worn hooks. Do not repair them by welding or reshaping.

b. Replace or repair all critical parts that are cracked, broken, bent, excessively worn, or missing.

c. Replace missing or illegible warning labels.

d. Replace pitted or burned electrical contacts as complete sets.

e. Keep controller function labels on pendant control stations and master switches legible.

7. Do not repair load-sustaining members by welding. Replace them as needed.

8. Lubricate all moving parts regularly using grease.

9. After maintenance work is completed and before restoring the hoist to normal operation:

a. Reinstall guards;

b. Reactivate safety devices;

c. Remove replaced parts and loose material;

d. Remove maintenance equipment.

Frequent Inspection

Perform the procedures in this section BEFORE INITIAL USE and AT LEAST MONTHLY. Inspection is needed more often for heavily used hoists.

1. Check operating mechanisms for proper operation, proper adjustment, and unusual sounds such as, but not limited to, binding noise of the wire rope and bearing squeal.

2. Check hoist upper limit device without a load on the hook at the beginning of each shift. Exercise care. Run the load block into its limit device at a slow speed.

3. Frequent Braking System Inspection

a. The braking system must automatically stop and hold up to the rated load if the operating controls are released and in the event of complete power failure.

b. Braking systems must limit the speed of load during lowering, with or without power, to prevent uncontrolled or rapid lowering.

4. Frequent Hook Inspection

Check hooks for the following problems:

a. distortion, such as bending, twisting, or increased throat opening; b. wear;

c. cracks, nicks, or gouges;

d. latch engagement (if equipped);

e. damaged or malfunctioning latch (if equipped);

f. hook attachment and securing means.

5. Frequent Hoist Rope Inspection. All ropes should be visually inspected by the operator or other designated person at the start of each shift.

6. Check wire rope reeving.

WARNING! TO PREVENT SERIOUS INJURY FROM HOIST

FAILURE: Do not use damaged equipment. If any defect or damage is noted, have the problem corrected before further use.

Periodic (Thorough) Inspection

The procedures in this section AT LEAST YEARLY. Inspection is needed more often for heavily used hoists.

Remove or open access covers to allow inspection of components.

1. First, follow all Frequent Inspection procedures.

Additionally:

2. Check fasteners for evidence of loosening.

3. Check load blocks, suspension housings, clevises, yokes, suspension bolts, shafts, gears, bearings, pins, rollers, and locking and clamping devices for evidence of wear, corrosion, cracks, and distortion.

4. Check hook retaining nuts or collars, and pins, welds, or rivets used to secure the retaining members for evidence of damage.

5. Check load sprockets, idler sprockets, drums, and pulleys for evidence of damage and wear.

6. Check the motor brake and load brake for evidence of wear.

7. Check the electrical apparatus for evidence of pitting or deterioration of controller contacts.

8. Check the supporting structure or trolley, if used, for evidence of damage.

9. Check the warning label for legibility and replacement.

10. Check end connections of wire ropes for evidence of wear, corrosion, cracks, damage, and distortion.

11. Check the hoist and hoist mounting for evidence of missing parts.

WARNING! TO PREVENT SERIOUS INJURY FROM HOIST

FAILURE: Do not use damaged equipment. If any defect or damage is noted, have the problem corrected before further use.

Storage Inspection

1. A hoist that has been idle for a month or more, but less than a year, must be inspected before being used according to the Frequent Inspection requirements.

2. A hoist that has been idle for a year or more, must be inspected according to the Periodic Inspection requirements and then tested according to the procedure in the Testing section below before being used.

Testing

1. Before use, test repaired hoists and hoists that have not been used for a year or more.

2. Check all functions of the hoist, including lifting and lowering, with the hoist unloaded first.

3. After testing in the unloaded state, attach a 200 Ib. load and retest to check proper load control and to check brake operation.

4. Test the trip-setting of limit devices under no-load conditions. Test first by hand, if practical, and then at the slowest speed. Test with increasing speeds up to maximum speed. Check that actuating mechanisms are located so that they will trip the switches or limiting devices in sufficient time to stop motion without causing damage to any part of the hoist.

Conclusion

In conclusion, the VEVOR Electric Hoist Manual provides comprehensive information on how to safely and efficiently operate the electric hoist. It is crucial to read and understand the manual before using the equipment to prevent accidents and injuries.

Regular maintenance checks and inspections are also necessary to ensure the hoist is in good working condition. With the VEVOR Electric Hoist Manual, you can operate your electric hoist with confidence and ease.