Introduction

Struggling to get a flat and solid surface on a construction site? Plate compactors: the solution you are looking for. However, improper use can potentially decrease performance and even create hazards. Fret not. This article will give you insights on “How to use a plate compactor effectively”. Through this understanding, you will optimize the performance and safety of your work. Whether you’re a pro or a newbie, using a plate compactor properly to achieve successful construction projects is a must. Now, let’s explore this equipment essential to completing your job quickly and satisfactorily.

Table of contents

Understanding the Plate Compactor

Uncover the information on components, types, and working of the plate compactor in the following section:

A. Components and parts

The main components that make up the plate compactor include:

Vibration Mechanism: The method uses the vibration mechanism to get the vibrations that cause compaction.

Handle: The operator can use the handle to control the compactor movement in different directions during the process.

Water Tank (Optional): Other plate compactors come with an embedded water tank designed to spray water across the surface that is being compacted. This, in turn, increases the effectiveness of the compaction.

Transport Wheels (Optional): If the plate compactor comes with wheels, maneuvering it from one location to another will be less complicated.

Engine/Motor Housing: The internal parts of the power unit, like the motor or engine, are encased and shielded by the housing.

Recoil Starter (Gasoline-powered): As for gasoline-engine plate compactors, they are normally equipped with a recoil starter that enables you to start the engine.

Throttle/Speed Control: The speed of the compactor is controlled by a throttle or speed control just like the process of compaction is controlled through operator manipulation.

Adjustment of Compaction Depth: Because of the depth compaction adjustment, you will be able to select the compression you desire.

Compactor Base/Plate: The plate or the substrate is a part of the compactor that comes in direct contact with the surface to be compacted.

Motor/Engine: The power source of the plate compactor is the engine or motor that provides the required force for compaction.

B. Key Types of plate compactors

Concerning the working principle, there are two main types of plate compactors:

Forward Plate Compactor: These uni-directional packers can compact granular soils and asphalt pavements.

Reversible Plate Compactor: Reversible plates provide flexibility to tamp it forward or backward. They are ideal for compacting cohesive soils because they produce tighter compaction in confined areas.

C. Working Principle of Plate Compactor

Plate compactors vibrate to realign particles, reducing the space between them and thus densifying soil. As you direct it, the compactor’s pressure and vibrations compress the material in its turn to get an even surface.

Stepwise Process on How to Use a Plate Compactor

Wondering “how to use a plate compactor?”. By following the below steps, you can efficiently and smoothly utilize your plate compactor:

Cleaning of Machine

Remember to clean your plate compactor and make it debris-free before operation. Remove the dirt, rocks, or anything that could affect its functionality. Machine cleaning ensures effective operation and extends the machine’s lifecycle by removing the debris that results in wear and tear.

Ensuring Optimum Tightness of Components

Components that are lost can cause the failure of operation systems or even accidents during operation. Take a close look at the plate, handle, and engine parts.

Loose parts tightening eliminates unwanted vibrations and results in a smooth and problem-free performance.

Maintaining Oil Level

Lube is an essential component of the engine. Verify the oil level is within the prescribed range. The effects of low oil levels include overheating and damage to the engine. Make sure to check the oil level often and, if needed, add oil to make the engine run efficiently.

Inspection/Prep of Site

Concerning “how to use a plate compactor” it is essential to check the work site carefully for obstacles, debris, or irregular terrain before using the plate compactor. Ensure the area has no debris or anything else hindering the compaction process. Secure a stable and compact ground, thus achieving the desired results. The right site preparation guarantees the security and proper functioning of the plate compact.

Machine Startup

After the place is ready, it’s time to begin the plate compactor. Follow the proper manufacturer guidelines to start the plate compactor. Make sure your engine is turned off before you try to start it. The appropriate operation of the machine requires a correct starting procedure.

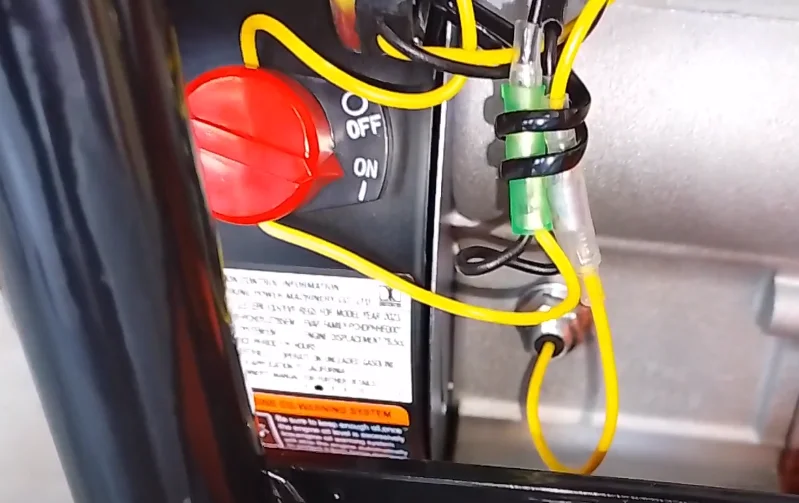

Fuel Cock Opening

If a gasoline engine powers your plate compactor, open the fuel cock to let the engine run on the fuel. Make sure there are no leaks and spills when you open the knob for fuel. The right fuel management is essential for the efficiency of the machine.

Choke Lever Closing

Before firing up the engine, pull the choke lever down to starve the carburetor of air. This enriches the fuel mixture, easing starting, particularly if the engine is cold. One can ensure an even engine start and avoid stalling by fully closing the choke lever.

Pull Starter Handle

First, close the choke lever, firmly hold the starter handle, and pull it smoothly to start the engine. Apply even pressure to prevent jolty movements, which can damage the starter mechanism. Repeat this motion until the engine starts.

Push The Throttle Lever To Start

After the engine starts, move the throttle lever to the start position. As a result, the engine works at low speed, gradually heating up. Running the motor at a low pace reduces the load on parts and maintains the engine’s smooth operation.

Engine Warm Up

Allow the engine to run for a while before starting the plate compactor. This means the engine oil runs well at its maximum operating temperature. Warm-up time is dependent on the engine type as well as ambient temperature.

Choke Lever Opening

Once the engine has warmed up, open the choke lever completely for the unobstructed airflow to the carburetor. This helps prevent an engine from running too rich and ensures efficient fuel utilization. Opening the choke lever also prevents the engine from stalling as you operate.

Tweak Speed Controller Low to High

Before compacting the soil and other materials, the speed controller needs to be adjusted to the desired level. Begin with a slow speed mode for lighter compaction tasks and increase the speed as heavier compaction is required. The speed control settings guarantee high-quality compaction and prevent overexertion of the engine.

Ensure Proper Positioning

As you use the plate compactor, be in a very stable position with feet a bit apart. Cling to the handles tightly and trying to maintain a stable grip to have the ability to control the motion of the machine. Place your body weight in the middle of your plate for stability and to avoid tipping.

Dealing With Obstacles and Irregular Surface

When complying with soil or other materials, you may encounter obstacles or uneven terrains. Slow it down and pay attention to the movements of your plate compactor so that you can work around obstacles and achieve a consistent compaction pattern.

Now you have an answer on “how to use a plate compactor” after reading the above section. Follow these steps and start today!

Safety Precautions of Plate Compactors

By taking all the safety measures needed to use plate compactors, you can avoid any accidents or injuries while working. The key precautions on the topic “how to use a plate compactor” are:

Lifting and Transportation:

Apply the proper lifting techniques and ask for help if the compactor is heavy and difficult to lift. You can use vehicles if needed. In transportation, double-check that the compactor is securely fastened so that it would not move or fall, possibly leading to injury or damage to the machine.

Follow Electrical safety

Before starting the electric plate compactor, do a first visual inspection for any signs of damage to the power cord. Extension cords with worn or frayed edges must not be used. To avoid electric shock, ensure the compactor is plugged into a grounded socket and never used in a wet environment.

Avoid loose clothing

Make your clothes fit tightly and don’t have anything caught up in machinery before using the compactor. Ensure that the working area is clear of any objects that may obstruct the operation of the compactor or provoke tripping.

Fueling and Engine Precautions

If it is a plate compactor with a gas-powered engine, refuel it in a well-ventilated area once it has cooled down to prevent flame or explosions. Never spill fuel, and clean up quickly if you do.

Employ Proper Storage:

When you finish using the plate compactor, store it in a dry and safe place to prevent damage from moisture or stealth robbing. Pull out the plugs of all the power sources and then neatly roll the cables up to avoid trips.

Do Not Relive These Mistakes

The key mistakes that many operators make while using the plate compactor. To address the query “how to use a plate compactor” properly you need to avoid the following mistakes:

Do Not Overload:

Nevertheless, try to stuff in a little bit of info in each go. There is a possibility that the machine may be overloaded, which could result in poor compaction and damage to the machines. Adhere to the maximum load capacity guide given by the manufacturers to obtain quality results and at the same time reduce the risk of machine failure.

Follow Scheduled Maintenance:

Routine maintenance is required to attain optimal performance from the plate compact. Not completing tasks such as checking oil, cleaning air filters, and adjusting belts will only disrupt the performance of your vehicle and result in expenses. Perform regular preventive maintenance to increase the lifespan of the gear and improve its effectiveness.

Stable Ground Operation:

The efficiency of the compactor is significantly affected when used on unstable or uneven fields and also security problems should be taken into account. Prior to the operation, confirm the surface is at level and made good for compaction. It is of great importance to avoid the soft spots, slopes and any type of waste that can cause instability or damage to the machines.

Employ Safety Protocols:

If you don’t obey or do not observe the essential security measures while using the plate compactor, you can be injured or suffer an accident. Make sure to use personal protective equipment for all-round protection. Comply with regulations and strive to be accident-free to ensure a safe workplace environment for you and others.

List of Top Durable Plate Compactors

The best-in-class plate compactors in the market that you can choose from are:

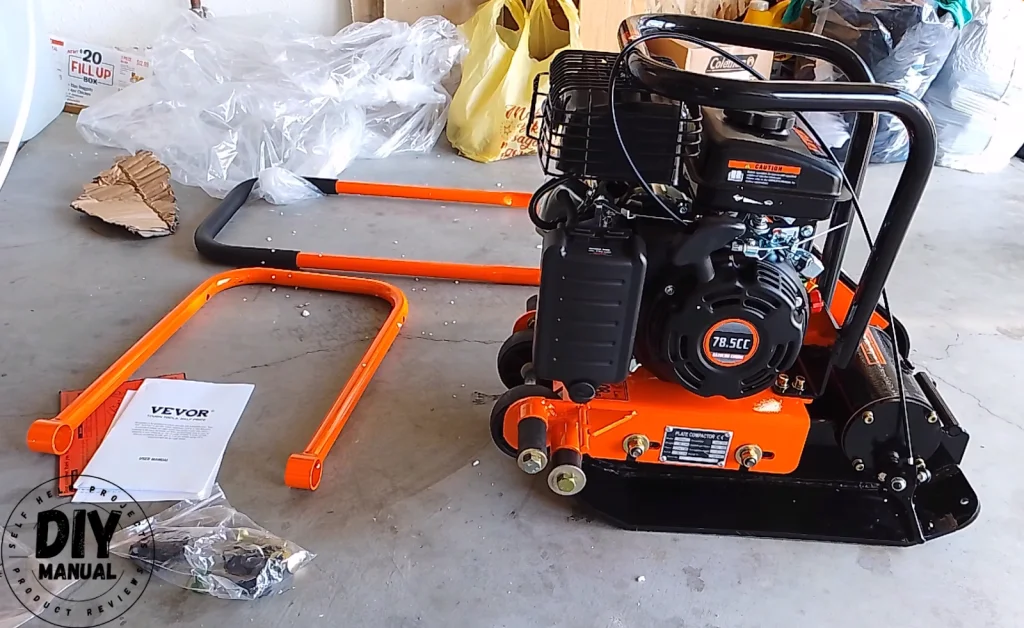

2.8 HP VEVOR Plate Compactor

The VEVOR Plate Compactor provides unmatched power with a 78.5 cc / 2.8 HP gas engine that delivers an impressive 5250 vibrations every minute. With its 8-inch compaction depth, 221 in² stamped area and 8 mm thickness, you’ll achieve the unmatched efficiency of up to 5400 ft²/h due to its tough design. Cruise comfortably on wide, wear- and tear-proof wheels that support up to 105.8 pounds. Adjust speed easily using the adjustable choke and linear throttle, with precision guaranteed for every road condition. Used by construction, municipal, highway and railroad projects ensure that dirt, gravel and many more are compressed professionally. Upgrade your roadwork today!

6.5 HP VEVOR Plate Compactor

Bring your projects to life with the VEVOR Vibratory Compaction Tamper, powered by a powerful 6.5 HP, 196CC gas engine delivering 5,600 VPM and 4,200 lbs force. Its 22.1 x 15.9-inch plate guarantees efficient walkways, asphalt, and paver landscaping compactions. Our compactors come with a spacious 351 in² stamped plate and 12-inch compaction depth, which enable you to maximize productivity by covering up to 7300 ft²/h. Manoeuvre effortlessly with wide, wear-proof wheels and a sturdy 146.6 lbs design. Manage speed easily through the synergistic effects of linear throttle and choke, which amplifies performance on any terrain. Rely on this versatile compactor for a great outcome in any work, from private to municipal.

FAQs

Uncover some frequently asked questions on “How to Use A Plate Compactor” right in the following section:

Should I sprinkle water on the ground before using a plate compactor?

For example, wetting the ground before using a plate compactor can improve your compaction efficiency, especially for clay or cohesive soils, by reducing friction. Yet, this is not necessarily needed. It depends on soil type and water content. Experiment with drying to achieve optimal results.

What is a plate compactor’s speed?

The speed of a plate compactor may vary depending on factors such as engine power, plate size, and soil type. A plate compactor can do 2-3 feet in a second, although this can differ.

What is the required weight of a compactor plate?

Choose plate compactor weight according to the type of the project and soil conditions. It could be a lighter model of around 100-150 pounds for small DIY projects. When working with a large scale or compacting harder soils, you may need heavier models weighing 200-300 pounds or more.

How long will a plate compactor go?

Plate compactors are very efficient for complying 6-12 inches deep layers, depending on the compactor’s weight, power, and soil conditions. Optimal compaction is achieved through multiple passes over the area, increasing the soil density progressively.

What are the pros of plate compactors?

Plate compactors provide benefits, including fast soil compaction, flexibility across different surfaces, simplicity in operation, and portability. They fill air voids in the soil, giving it stability and higher load-bearing capacity, vital in construction projects like road construction, driveways and foundations.

Conclusion

In summary, efficiently using a plate compactor will be very important in your projects. By implementing the above “How To Use A Plate Compactor” guide, you can achieve successful and high-quality compaction every time. Make sure to pick the one that is appropriate for your project. VEVOR provides a variety of premium items that are perfect for all kinds of jobs. Choose today the best plate compactor from VEVOR to enjoy your construction site’s even and long-lasting surfaces. You can also get a variety of masonry concrete tile tools from VEVOR. Don’t compromise on quality, purchase quality equipment and raise your construction game now.