You use wire-cutting machines to make your work easier. Regular maintenance keeps your machines from breaking down and extends their lifespan. If you take care of them, you won’t have to fix them as often, you’ll save money, and you’ll get more done each day. You keep your machines safe and make sure every job is done well if you stay ahead.

Maintenance Tips for Wire Cutting Machines

Taking care of your wire cutting machines helps you avoid trouble. You get better results when you look after them. Try these tips to keep your machines working well every day.

Cleaning and Debris Removal

It is essential to keep your machine clean. This stops damage and helps it work well. Dust, wire scraps, and oil can pile up quickly. Wipe the surfaces and remove loose bits every morning. Focus on the cutting area and guides. Cleaning the tank matters because leftover stuff can mess up wire alignment and cutting quality. Use a soft brush or vacuum for hard spots. Clean the tank once a week to stop buildup. Check your machine after each job to keep it tidy.

Lubrication of Moving Parts

Lubrication helps moving parts last longer. Check your machine’s manual for the correct oil. Put oil on gears, bearings, and guides every day. Check lubrication points during your weekly checklist. If you see dry spots or hear squeaks, add more oil. Checking and adding oil often stops big repairs. Good lubrication helps with tension adjustment and wire replacement.

Checking Filters and Sensors

Your machine will work better and be safer with filters and sensors. As part of your regular maintenance, check the filters every week. Dirty filters can block airflow, causing the machine to overheat. When they need it, clean or change them. Sensors help adjust the tension and align the wires. Check the sensors monthly to ensure they work. If you see mistakes or the sensor is slow to respond, clean the area around it and look for loose wires.

Calibration for Accuracy

Calibration ensures that your wire-cutting machines cut to the correct size and shape. Keep track of calibration jobs with your machine’s checklist. Every month, check the guides and cutting head to make sure they are working right. This keeps the wire in line and prevents uneven cuts. Recalibrate right away if you change the wire size or replace the wire. Calibration also helps you adjust the tension, which keeps your machine accurate.

Software Updates

Software controls cutting and wire alignment in modern wire cutting machines. Check for new information every month. Software updates fix bugs and add new features. To update safely, follow the maker’s instructions. Keep a log of all the updates you make to your general maintenance. When you update your software, it helps you find problems early and makes your computer run better. This is a simple table to help you keep track of when to do maintenance:

| Task | Daily | Weekly | Monthly |

| Clean machine surfaces | ✔️ | ||

| Cleaning the tank | ✔️ | ||

| Lubricate moving parts | ✔️ | ✔️ | |

| Check filters/sensors | ✔️ | ✔️ | |

| Calibrate machine | ✔️ | ||

| Software updates | ✔️ | ||

| Wire replacement | As needed |

Preventive Maintenance Measures

Maintenance Schedule

You need a clear plan to keep your wire-cutting machines running smoothly. A good schedule tells you when to clean, check, and replace parts. You can use a table or a calendar to track each job. This helps you remember to clean, oil, and check your automatic wire crimping machine. When you follow a plan, you stop sudden problems and keep your automatic machines working properly.

Operator Training

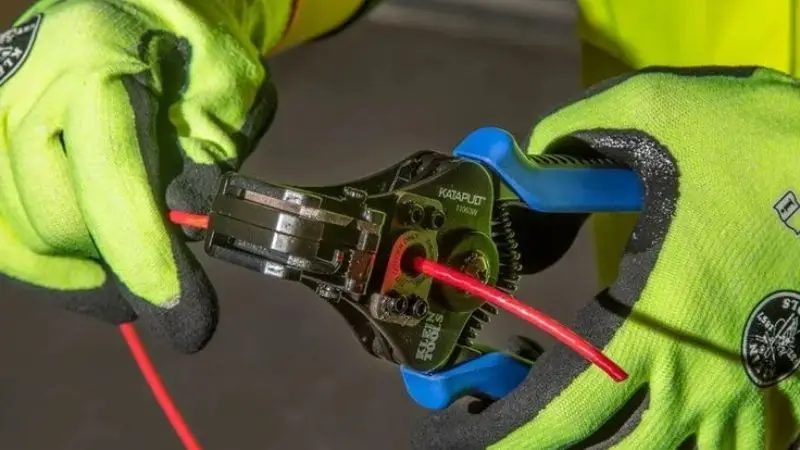

Every operator must learn how to use an automatic wire crimping machine or stripper. Training teaches safe use and proper care of the machine. When you know how to use it, you can find problems early. You also learn how to clean and check the machine properly. Good training helps you avoid mistakes that could hurt the automatic wire crimping machine or stripper.

- Teach each operator how to use the machine safely.

- Show how to clean and check the machine often.

- Go over safety rules many times.

Quality Replacement Parts

Always use high-quality replacement parts for your stripper and automatic wire crimping machine. Cheap or incorrect parts can break things. Good parts make your machine last longer and work better. You can keep your automatic machines safe and lower the chance of problems by using the right parts.

Monitoring Performance

Every day, you need to check on how your automatic wire crimping machine and stripper are doing. Check for cuts that are too slow, strange sounds, or mistakes. Keep a record of any changes. This helps you find problems early. When you watch performance, you can fix minor issues before they get worse. Regular cleaning and inspection often make this easier.

Common Automatic Wire Cutter and Stripper Issues

When you use wire cutting machines, you may face different problems. Knowing how to fix these issues helps you keep your work moving. This guide on troubleshooting common automatic wire cutters and strippers will help you solve the most frequent problems.

Wire Breakage

Wire breakage can stop your work and waste material. You need to find the cause quickly. Start by checking the cutting depth of the best wire cutting machines for small workshops. If the blade cuts too deeply, it can snap the wire. Adjust the blade so it only cuts through the insulation, not the wire itself. Check the wire guides and make sure they align with the wire path. Misaligned guides can bend or break the wire. Examine the tension settings. Too much tension pulls the wire too hard, causing breaks. If you frequently see wire breakage, clean the cutting area. Dirt and debris can block the wire, causing it to snap.

Uneven or Inaccurate Cuts

Uneven or inaccurate cuts lead to poor results. You may notice wires occasionally not cut to the correct length. First, check the calibration of your machine. If the cutting head is misaligned, the wire will not cut evenly. Use your machine’s calibration tool to reset the cutting head and guides.

Check the sensors that measure wire length. Dirty or faulty sensors can send wrong signals. Clean the sensor area and make sure all wires are connected. If you still see problems, look at the blade for wear. A dull blade can cause uneven cuts. Here is a quick checklist for uneven cuts:

- Check calibration settings.

- Clean and test sensors.

- Inspect the blade for sharpness.

- Make sure the wire feeds straight.

Error Codes

You may see error codes on your machine’s display. These codes help you find the problem fast. When you get a wire cut error, read the code and look it up in your manual. Most codes indicate whether there is a sensor issue, a jam, or a software problem.

If you see a sensor error, check the sensor for dust or loose wires. For jam errors, remove any stuck wire or debris. If you get a software error, restart the machine and check for updates.

Power and Connectivity Problems

Power and connectivity problems can stop your machine from working. If the machine does not turn on, check the power cord and plug. Make sure the outlet works. If the machine starts but stops during use, look for loose connections inside the control panel.

Sometimes, the machine loses connection with the computer or control system. Check all cables and ports. Restart both the machine and the computer. If you use network controls, make sure the network is stable.

When to Call a Professional – Troubleshooting Tips

Complex Problems

You can fix many minor issues with your wire-cutting machine by following basic troubleshooting tips. Sometimes, you face problems that go beyond simple fixes. If you see repeated error codes, machine parts that do not move, or strange noises that do not stop, you should stop using the machine. These signs often indicate a deeper issue within the machine.

You may also notice that your troubleshooting guide does not help with the problem. If you try all the steps and the machine still does not work, you need expert help. Electrical faults, software crashes, or broken internal parts require a trained technician. Trying to fix these on your own can make things worse or cause injury.

Choosing Service Providers

When you need help, choose a service provider who knows your machine well. Look for companies with experience with wire-cutting machines. Ask if their technicians have training from the machine’s maker. You can check reviews or ask other users for advice. Here are some tips for choosing the right provider:

- Ask about their experience with your machine model.

- Check if they offer a warranty on repairs.

- Make sure they use quality replacement parts.

- Find out how fast they can respond to your call.

| Question to Ask | Why It Matters |

| Do you know my machine? | Ensures proper troubleshooting |

| Do you use genuine parts? | Keeps the machine safe |

| How soon can you come? | Reduces downtime |

Conclusion

You keep your wire-cutting machines running smoothly by following a robust maintenance plan. Clean the tank weekly and check it after each job. Watch the tank for dirt and wire scraps. Remove debris from the tank to stop problems. Inspect the tank for leaks or damage. Use clean filters in the tank to improve the machine’s performance. Change filters when you see dirt. Filters protect the tank and keep the machine safe. Write down tank checks in your log. Replace filters often. Good care of the tank and filters helps your machine last longer.

FAQ

How often should you clean your wire cutting machine?

You should clean your machine every day. Remove dust and wire scraps after each job. Clean the tank once a week. This habit keeps your machine safe and working well.

What is the best way to prevent wire breakage?

Check the cutting depth before you start. Use the correct wire diameter setting. Clean the guides and cutting area often. Watch for signs of wear on the blade.

Why is calibration important for wire cutting machines?

Calibration helps your machine cut wires to the right size. You get better results and fewer mistakes. Calibrate your machine every month or after changing wire sizes.

When should you call a professional for repairs?

Call a professional if you see repeated error codes, hear strange noises, or smell burning. Do not try to fix electrical faults or software crashes by yourself.

What is wire EDM maintenance, and why does it matter?

Wire EDM maintenance means taking care of your machine with regular cleaning, lubrication, and checks. You prevent breakdowns and keep your machine running longer. Good maintenance saves money and improves performance.