A wire stripping and cutting machine should give you fast and accurate results. You need a tool to handle single, multiconductor, or coaxial wires with ease. New programmable, semi-automated machines can help you save valuable time. These machines allow you to process wire safely and quickly. When working with moving parts and sharp blades, safety is paramount. Select a machine to help you cut and strip the wire without errors.

- Why Professional Wire Cutting and Stripping Machines Are Essential

- Key Features to Look for in Wire Cutting and Stripping Machines

- Best Wire Cutting and Stripping Machine Picks

- Key Features to Look for in Wire Cutting and Stripping Machines

- Comparison Table and Quick Reference

- How to Choose the Right Wire Cutting and Stripping Machine

- Tips for Maintaining Your Wire Cutting and Stripping Machine

Why Professional Wire Cutting and Stripping Machines Are Essential

Using professional wire cutting and stripping machines means faster work and fewer errors. When it comes to daily wiring tasks, the benefits of using a wire cutting and stripping machine stand out in speed, precision, and consistency.

Benefits of Using Professional Machines

If you have to work with wires every day, a wire-stripping machine will save you both time and effort. Professional machines can help you complete jobs faster with fewer errors. This means that you will not waste money or wire because of clean cuts. Wire stripping machines also protect your hands from blades. These machines can handle a wide range of wires, including thin single wires and thick cables. Many professionals also choose an electric wire stripping machine for smoother and quicker operation.

Tip: Use a professional wire-stripping machine to keep your workspace clean and orderly. Spend less time cleaning and more time working.

Professional machines are often equipped with automatic features. You can set the depth and length of each cut using these features. No need to guess or manually measure. It makes your work easier to repeat and more accurate. A wire stripping tool can be used for large projects or smaller repairs. You can meet deadlines with the right machine and make your customers happy.

Differences Between Manual, Semi-Automatic, and Automatic Machines

There are three types of wire stripping machines: semi-automatic and automatic. Each type is best suited to different tasks.

- You will need to pull or turn a lever on a manual wire stripping device. You can control the speed and force. Manual machines are good for small jobs or when there are only a few cables to be stripped. These machines are cheaper, but require more effort.

- An automatic stripping machine takes care of almost all your needs. The wire is loaded, the program is set, and the machine starts. The machine strips and cuts the wires without any help. This demonstrates how an automatic wire cutting and stripping machine works and why it is ideal for large volumes. Automatic machines are best for large projects or if you have to strip wires on a regular basis.

When you choose the right wire stripping and cutting machine for your needs, you will get the best results. It can help you save time, prevent mistakes, and keep your hands protected.

Key Features to Look for in Wire Cutting and Stripping Machines

You should focus on the features that are most important when choosing a wire stripping and cutting machine. These features will help you achieve the best results and make your job easier. Always look for machines with flexibility, safety, and high performance.

Adjustable Wire Length and Stripping Settings

It is important to have a machine where you can set the length of the wire and the stripping depth. You can use this feature to work with a variety of wire types and sizes. The same machine can be used for multiple jobs. You can input exact measurements on some machines that have digital controls. Some machines use levers or dials to make quick adjustments.

- Adjustable Settings help you avoid mistakes.

- Save time by not having to measure manually.

- Every time you cut, the result is a clean and repeatable cut.

Tip: Choose a machine that has easy-to-use adjustment features if you work with a variety of wire types. You can switch jobs more quickly.

Durability and Build Quality

You want to buy a machine that will last for many years. You use your machine every day, so durability and build quality are important. You should look for machines that are made of metals such as steel or aluminium. Look for a solid construction with tightly-fitted parts.

You will spend less on repairs and replacements if you buy a machine that is well-built. Spend less on repairs and new machines. You will also be safer because strong machines do not wobble during use.

- Heavy-duty machines are designed to handle the toughest jobs.

- Quality parts mean fewer breakdowns.

- You can enjoy peace of mind with a sturdy machine.

Focusing on these features will ensure that your machine works well and is durable. You can finish your work quickly and achieve better results.

Best Wire Cutting and Stripping Machine Picks

You can work faster by choosing the best wire cutting and stripping machine for small businesses or large professional setups. You will also be safer on the job. It is important to choose a machine that will suit your needs. The machine should be suited to the size and type of wire that you are using. Here are a few top choices for professionals. Each machine offers its own unique features and benefits. This guide will help you find the right heavy-duty wire stripping machines for your needs.

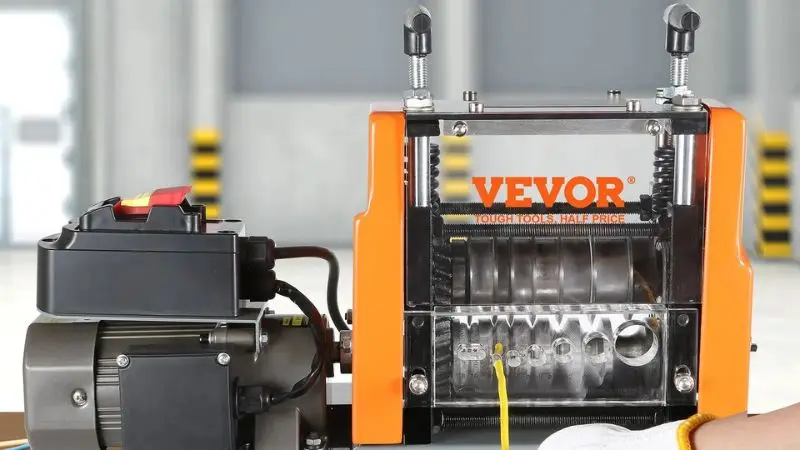

Best Overall: VEVOR Wire Cutting and Stripping Machine

You need a machine that can cut and strip many different types of wire. VEVOR’s wire stripping machines are strong and reliable. This heavy-duty machine strips single, multiconductor, and coaxial wire. It can be used for copper, aluminium, and other materials. You can use the VEVOR with a manual crank or an automatic motor. You can use it for both small and large jobs.

Features:

- Wire sizes range from 1.5mm to 25mm.

- Both manual and automatic operation.

- Made from heavy-duty steel to ensure long-lasting durability.

- Easy to adjust for different types of wire.

Note: It is possible to switch between automatic and manual modes. It is easier to use. When you have a lot of wires to strip, it saves time.

The VEVOR wire-stripping machine will give you clean strips and cuts. The same results are achieved every time. This machine is perfect for professionals who use a wire stripping machine on a daily basis.

Best Overall: Eubanks AutoStrips

A wire stripping machine must be fast and accurate. Eubanks AutoStrips’ wire stripper is best for professionals looking for high-performance wire cutters. This automatic wire stripping and cutting machine has programmable settings. Digital controls allow you to set the stripping depth and wire length. This model clearly shows how an automatic wire cutting and stripping machine works with precision and speed.

Features:

- The machine can process up to 10,000 cables per hour.

- Work with single, multiconductor, and specialty wire.

- Automatically adjusts the wire size.

- The heavy-duty construction is ideal for large jobs.

Tip: Program the features to suit high-volume jobs. The same results are achieved with fewer errors.

The Eubanks Wire Stripping Machine is extremely precise. This heavy-duty wire stripping tool is the best choice for difficult projects.

Best Budget: Stripmeister Wire Stripping Machine

Stripmeister is the best choice if you are looking to save money. This manual wire stripping and cutting machine is ideal for small shops or DIY users. For less money, you can get a powerful electric wire stripping machine. Stripmeister’s wire stripper uses a manual crank. You can easily strip copper and aluminium wire.

Features:

- Strip wire sizes range from 18 AWG up to 250 MCM.

- You have more control with manual operation.

- Aluminum frame with a heavy-duty design.

- Simple to install and use.

Tip: Stripmeister is easy to use. Strip wire quickly without spending much.

This is the best wire stripper for small jobs. This heavy-duty wire stripping machine is built to last.

Best for Precision: Programmable Wire Cutting and Stripping Machine

For small wire work, you need to be precise. You can achieve perfect results with programmable wire stripping and cutting machines. These automatic wire stripping machines use digital controls. You can adjust the stripping depth and speed, as well as the length of wire. Wire cutters with high performance for electronic, telecom, and laboratory work.

Features:

- Programming is easy with the digital display.

- It can be used with wires ranging from 0.1mm to 10mm.

- Automatically feeds and cuts the wire.

- Built for everyday use.

Note: You can avoid making mistakes by using a programmable wire stripping machine. You will get perfect strips each time.

This best wire stripper is ideal for tasks that require high accuracy. This heavy-duty wire stripping machine is best for thin and small wires.

Best for High Volume: Semi-Automated Wire Stripper Machine

For large quantities of wires, you will need a wire-stripping machine. Semi-automatic machines combine manual feeding and automatic cutting. Both speed and control are available. These machines are ideal for large workshops and factories. You can remove thousands of wires per day.

Features:

- Semi-automatic operation to speed up work.

- Work with wire sizes ranging from 2mm to 20mm.

- Heavy-duty steel frame

- Easy to adjust for different types of wire.

Tip: Use semi-automatic machines to strip wires for large jobs. You will save time and be less tired.

This top wire stripper gives you a steady performance. This heavy-duty wire stripping machine is perfect for difficult jobs.

Best for Specialty Cables: Coaxial and Multiconductor Wire Stripping Machine

For special cables, you need a wire-stripping machine. Wire stripping machines for coaxial and multiconductor cables have unique features. You can easily strip cables that are difficult to work with. These machines are designed to cut and strip wires automatically. They use sharp blades with programmable settings.

Features:

- Strips of coaxial wire, ribbon, multiconductor, and other similar products.

- Automatically adjusts cable type.

- Professional design with heavy-duty construction.

- Easy-to-use digital controls.

Note: You can use specialized wire stripping machines to create cables with unique characteristics. The wire core is kept safe, and you get clean strips.

This best wire stripper can be used for audio, data, and telecom cables. This heavy-duty wire stripping machine is great for tough jobs.

Comparison Table: Best Wire Stripper Machines

| Machine Name | Operation Type | Wire Size Range | Heavy-Duty Build | Precision Level | Ease of Use | Best For |

| VEVOR | Manual/Automatic | 1.5mm-25mm | Yes | High | High | All-around |

| Eubanks AutoStrips | Automatic | Various | Yes | Very High | High | High volume, precision |

| Stripmeister | Manual | 18 AWG-250 MCM | Yes | Medium | High | Budget, small jobs |

| Programmable Machine | Automatic | 0.1mm-10mm | Yes | Very High | High | Precision jobs |

| Semi-Automated Machine | Semi-Automatic | 2mm-20mm | Yes | High | High | High volume jobs |

| Coaxial/Multiconductor | Automatic | Various | Yes | Very High | High | Specialty cables |

Tip: Use this table to find the right wire stripper for you. Consider the wire size range, operation type, and build quality.

The right machine for you will depend on the size of your wire and your task. Wire stripping machines have special features for professionals. The best wire stripper machines will give you better results and allow you to save time.

Key Features to Look for in Wire Cutting and Stripping Machines

Before buying the wire cutting and stripping machine, these are the key features you must look for.

Adjustable Wire Length and Stripping Settings

It is important to have a wire cutter you can control. Adjustable Settings allow you to choose the length and depth of the wire. It helps you to do the job correctly. Some machines have dials to change the settings. Some machines have digital controls that work automatically. You can choose between manual and automatic modes. You can use these features to work with a variety of wire sizes. You can save time by making fewer errors.

Tip: For large jobs, use automatic settings. Manual controls are best for special wires.

Durability and Build Quality

A heavy-duty cutter is able to handle the daily tasks. Metal is the best material for a machine. Search for parts made of steel or aluminum. Heavy-duty machines are more durable and perform better. Manual machines with sturdy frames are less likely to break. Automatic machines can handle tough jobs. You need a wire cutter that feels steady and safe.

- The heavy-duty construction means less maintenance.

- You can work more efficiently with strong machines

Speed and Efficiency

Automated machines help you work faster. Automated machines can help you finish jobs faster. The machines can cut and strip wire faster. Manual machines are great for small jobs. Automated machines can save time for large projects. Heavy-duty machines are able to process more wire quickly. With less effort, you can do more. Even when you work quickly, you still get great results.

| Machine Type | Speed Level | Best Use |

| Manual | Low | Small jobs |

| Automatic | High | Large projects |

| Heavy-duty | Very High | Daily, tough use |

Safety Features

When using a wire cutter, safety is paramount. You should look for machines that have blade guards or emergency stops. Safety parts are often added to heavy-duty machines. Automatic machines protect your hands from blades. Safety features on manual machines help prevent accidents. Wire stripping machines that are safe for you and your team will keep them both protected.

Note: Check safety features before working with wire.

Comparison Table and Quick Reference

Here is the quick comparison table of wire stripper machines

Feature Comparison of Best Wire Stripper Machines

The right machine is crucial to your success. You can compare machines in the table below. Check which machines work with different sizes of wire. Also, you can check if it is easy to operate and heavy-duty. This guide will help you decide what best suits your needs.

| Machine Name | Operation Type | Wire Size Range | Heavy-Duty Build | Precision Level | Ease of Use | Best For |

| VEVOR | Manual/Automatic | 1.5mm-25mm | Yes | High | High | All-around |

| Eubanks AutoStrips | Automatic | Various | Yes | Very High | High | High volume, precision |

| Stripmeister | Manual | 18 AWG-250 MCM | Yes | Medium | High | Budget, small jobs |

| Programmable Machine | Automatic | 0.1mm-10mm | Yes | Very High | High | Precision jobs |

| Semi-Automated Machine | Semi-Automatic | 2mm-20mm | Yes | High | High | High volume jobs |

| Coaxial/Multiconductor | Automatic | Various | Yes | Very High | High | Specialty cables |

Tip: Use this table to find the right machine for your job and wire size. Choose a machine that is heavy-duty and will save you time.

Pros and Cons Summary

It is important to know where each machine excels and where it falls short. This list will help you decide which machine is right for your job.

- VEVOR

- Work with many different wire sizes and types

- Both manual and automatic options are available

- Some wires require more setup

- Eubanks AutoStrips

- Fast and accurate for large jobs

- High precision digital controls

- Manual machines are more expensive

- Stripmeister

- Easy to use and good price

- A strong frame will last a long time

- Large jobs are slow to be done by hand

- Programmable Machine

- Perfect for precision jobs

- Automated settings reduce the need for repetitive work

- New users may find it difficult to use

- Semi-Automated Machine

- Combines speed with control well

- The heavy-duty construction is ideal for everyday work

- The wire must be fed manually

- Coaxial/Multiconductor

- Special cable types

- It works well with wires that are tricky

- Simple wire jobs do not require a splice tool

Note: There are pros and cons to each heavy-duty wire stripping machine. Choose the machine that best suits your needs.

How to Choose the Right Wire Cutting and Stripping Machine

With so many models out there, how do you know which one is truly worth it? These simple guidelines will help you narrow down options and avoid costly mistakes.

Assess Your Business Needs

Start by thinking about what you do every day. You should ask yourself how many wires to cut and strip per day. You may need an automatic machine to strip wires if you handle many wires. Manual machines may be better suited for those who only work with a few wires. Consider the type of wire that you will be using. Some jobs require a machine capable of handling thick cables. Some jobs require a machine that can handle small wires or specialty wires. List your most popular wire types and sizes.

Tip: Note down the top three jobs you do with wire. You can then choose the best wire stripping machine to suit your needs.

Compare Machine Specifications

Check the features on each wire stripping machine. Check the range of wire sizes. Some machines can handle very thin wires, while others can handle thick cables. Choose machines that have adjustable settings. You can adjust the depth and length of each wire. Choose an automatic machine if you want to save some time. Automated machines can handle many wires at once. Compare the main features using a table.

| Feature | Manual Machine | Automatic Machine |

| Wire Size Range | Limited | Wide |

| Speed | Slow | Fast |

| Ease of Use | Simple | Very Easy |

| Best For | Small jobs | High volume |

Read Reviews and Testimonials

It is important to read what users have said about the wire stripping machines. You can find out from reviews if the machine is compatible with your wire type. You can find out about the speed of the machine, its safety, and ease of use by reading comments. Many professionals offer tips on how to use automatic machines. Their experience can be useful to you. You can avoid machines that break or strip wires in an unclean manner by reading good reviews.

Note: Check for the latest reviews. New models of machines may be better suited to your wire work.

Tips for Maintaining Your Wire Cutting and Stripping Machine

Good maintenance doesn’t have to be complicated. Here’s how to keep your wire cutting and stripping machine running smoothly.

Regular Cleaning and Lubrication

To get the best results, you need to keep your Wire Stripping Machine clean. Dust and wire fragments can accumulate inside the machine. You can extend the life of your machine by cleaning it after every use. Remove wire scraps with a soft toothbrush from the gears and blades. Wipe surfaces with a clean, dry cloth. Lubricate moving components with a little machine oil. This will keep the wire stripping machines running smoothly and help you to avoid jams.

Tip: Clean your wire stripping machine every day. Regular cleaning prevents wire fragments from becoming a problem.

Replacing Blades and Components

Sharp blades will help you strip and cut wire without making mistakes. Check the blades if you find that the machine is not cutting cleanly. Blades that are dull can cause the wire to be damaged and slow your work. Replace the blades if you notice wear or rough edges. Check other parts, such as rollers and guides. Replace any broken or loose components immediately. It will keep your wire stripping machines in good working order.

- Check blades at least once a week.

- Replace worn-out parts before they break.

- Only use parts that are made specifically for your wire stripping machines.

Safety Checks and Calibration

Before you begin, make sure that your machine is safe. Check for loose screws and covers. Blade guards should be in place. Check if the emergency stop button works. The machine should be calibrated so that it strips and cuts wires at the correct length and depth. Test the settings with a test cable. Adjust the controls if you find any mistakes. Regular safety checks will help you to avoid accidents and ensure that your wire stripping machines are ready for any task.

| Maintenance Task | How Often | Why It Matters |

| Clean and lubricate | Daily | Stops wire jams |

| Replace blades | Weekly | Keeps wire cuts clean |

| Safety check | Before use | Protects you from harm |

| Calibrate settings | Monthly | Ensures wire accuracy |

Note: It is important to maintain your machine properly so that it will last longer.

Conclusion

The top wire stripping and cutting machines for 2025 are now available. Check the safety features and match your machine to the wire job. Compare the machines to decide which one is best for you. For more information, you can read reviews by experts or ask suppliers to show you a machine. You can work faster and more safely with the right wire cutting and stripping machine.

FAQ

What types of wire can you use with these machines?

You can use these machines for copper and aluminum wires. They work with single-core, multiconductor, and coaxial wires too. Some machines can handle special cables. Always look at the machine’s details before you start.

How often should you replace the blades?

Check the blades every week to see if they are sharp. Change them if you notice dull edges or rough cuts. Sharp blades help you make clean strips and keep your wires safe.

Are automatic wire stripping machines safe to use?

Automatic machines have safety parts like blade guards and emergency stops. Always read and follow the safety rules. Test the emergency stop button before you use the machine to stay safe.

Can you use one machine for different wire sizes?

Many machines let you adjust the settings. You can change the wire length and how deeply you strip it. This means you can use one machine for many wire sizes and types.

What maintenance does your wire stripping machine need?

Tip: Clean your machine every day. Put oil on moving parts. Check for loose screws and worn blades. Taking care of your machine helps it last longer and work better.