Wire strippers that self-adjust can help you quickly and easily remove the insulation from wires. It is not necessary to guess at the size of wires or adjust settings. You will always get the exact results you want. These tools are used by electricians, DIYers, and professionals to complete wiring projects in the home or at work. These tools can be used to fix outlets or set up control panels. Many people prefer self-adjusting wire strippers because they make the work faster and more precise.

- What Are Self-Adjusting Wire Strippers?

- How Self-Adjusting Wire Strippers Work

- Benefits of Self-Adjusting Wire Strippers

- How to Choose the Best Self-Adjusting Wire Stripper

- Step-by-Step Guide: How to Use a Self-Adjusting Wire Stripper

- Common Mistakes to Avoid

- Maintenance Tips to Extend the Life of Your Wire Strippers

- Self-Adjusting Wire Strippers vs. Automatic Wire Strippers

- Common Questions and Misconceptions

- Conclusion

What Are Self-Adjusting Wire Strippers?

Self-adjusting wire strippers help you remove the insulation from wires without having to guess their size. They can be used on a variety of wire types, including solid core and stranded. These tools are suitable for wires ranging from 10 AWG to 24 AWG. These wires are often used in car repair, home wiring, and control panels. Electricians working on large projects often look for tools like the best self-adjusting wire strippers for electricians to get consistent results.

How They Differ from Manual Strippers

You must match the size of the wire to the notch on the manual wire strippers. Each time you change wires, you must adjust the tool and check the gauge. This can lead to errors and slow down your work. Wire strippers that automatically adjust themselves do not require you to alter the settings. The tool grabs the insulation and grips the wire with one movement. The tool saves time and prevents damage to the wire. This is also why many DIY users prefer automatic wire strippers for home use when handling quick tasks.

Self-adjusting wire strippers will make your work much easier if you are working with electrical panels or projects that have many different types of wires.

Key Features and Mechanism

These tools are distinguished by several features:

- Automatic adjustment: The tool detects the size of the wire and adjusts its grip.

- Compatible with both solid and stranded cables.

- Clean cuts: Blades are designed to remove insulation without damaging the wire.

- Some models have a built-in length stop that allows you to set the amount of insulation you want to remove.

The mechanism is a pair of jaws that clamp onto the wire. One jaw grips the wire, while the other removes the insulation. This action is smooth and works for all wire types and sizes. Every time you get a consistent, clean strip. This versatility is helpful if you need a self-adjusting wire stripper for multiple wire sizes in your projects.

How Self-Adjusting Wire Strippers Work

These wire strippers save time by adjusting to the wire’s thickness. They automatically fit the wire, remove insulation precisely, and reduce the risk of damaging the conductor.

Step-by-Step Operation

Wire strippers are easy to use. Grab the wire that you wish to strip. It should be placed between the jaws. The blades should be aligned with the part that you wish to remove. Squeeze together the handles. The tool grabs the wire in one movement and removes its insulation. The wire is not damaged, and you get a neat strip.

Here’s a quick checklist to follow:

- Choose the wires you wish to strip.

- The wire should be inserted into the jaws.

- Align the blades with the wire.

- Firmly squeeze the handles.

- Remove the stripped wire.

Online, you can find many videos that show how to use wire strippers with self-adjusting capabilities. You can learn how to use the wire strippers by watching a video.

Mechanism Explained

Self-adjusting wire strippers use a smart mechanism. Jaws detect the thickness of the wire. One jaw will hold the wire in place when you squeeze the handles. The other jaw removes the insulation. Blades can be adjusted to the size of the wire. No settings need to be changed.

Some models, like those by IRWIN and Greenlee, include extra features. A swivel knob may be used to adjust the length of the strip. For repeating tasks, you may find a length stop built in. These features allow you to work faster while getting the same results each time. Professionals who need high-performance tools often choose a professional automatic wire stripping tool for durability.

The table below shows the different types of wires and how they work.

| Wire Type | Jaw Action | Blade Adjustment | Result |

| Solid Core | Firm grip | Auto adjust | Clean strip |

| Stranded Wire | Gentle grip | Auto adjust | No damage |

Self-adjusting wire strippers can be used for a wide range of wire types and sizes. This tool will make your job safer and easier.

Benefits of Self-Adjusting Wire Strippers

Using self-adjusting wire strippers increases accuracy, speeds up projects, and minimizes the chance of damaging wires, making electrical work much easier. Some of the benefits are listed below

Speed and Efficiency

Wire strippers that automatically adjust themselves can save you time. You can save time by using wire strippers that automatically adjust. It is not necessary to change the settings for every wire size. Insert the wire, then squeeze the handle. The insulation is stripped in one movement. Work faster and accomplish more tasks.

These tools are used by many professionals because they accelerate repetitive tasks. Strip dozens of wires at once without slowing down.

Precision and Consistency

For safe connections, you need to use clean and accurate strips. The same results are achieved every time with self-adjusting wire strippers. Blades grab the wire to remove insulation without cutting the metal. Avoiding mistakes such as nicks in wires and uneven strips. Your work is neat and adheres to safety standards.

| Benefit | Manual Stripper | Self-Adjusting Wire Stripper |

| Consistent Strips | Sometimes | Always |

| Risk of Damage | Higher | Lower |

| Clean Finish | Varies | Reliable |

Versatility for Wire Gauges

You work with different sizes of wires. Wire strippers that self-adjust can handle gauges from 10 to 24 AWG. It is not necessary to change tools or adjust jaws. With the same tool, you can strip both solid core and stranded cables. This versatility will make your toolbox lighter and your job easier.

- Work with both solid and stranded cables

- Handles multiple wire gauges

- This product is useful for automotive, home, and industrial projects

Ergonomic Design

It is important to choose a tool that feels good in your hands. Many self-adjusting wire strippers feature ergonomic handles. These ergonomic handles help reduce fatigue in the hands, especially if you are working for long periods. Shaped to fit your hand, it helps you use less force. Some models have swivel buttons and length stops built in. You can easily repeat the same operation by using these features.

Choose a model that has adjustable stops and padded grips if you are prone to stripping wires frequently. After a long, tiring day, your hands will be grateful.

The tool is easy to use, produces precise results, and feels great in your hands. Wire strippers that self-adjust can help you work more efficiently.

How to Choose the Best Self-Adjusting Wire Stripper

Types and Models

In stores, you will find a variety of wire strippers. Some models are best suited for DIY projects, while others are better suited to professional tasks. Compact designs may be available that are small enough to fit in your pocket. Larger models have more features to handle heavy-duty tasks. Brands such as IRWI, N Greenlee, and Phoenix provide reliable options. Choose a basic model for simple repairs, or a high-end model for frequent usage.

| Model Type | Best For | Example Brand |

| Compact | DIY, quick fixes | IRWIN |

| Heavy-Duty | Industrial work | Greenlee |

| Multi-Function | Versatile tasks | Phoenix |

Tip: Pick a model with a range of gauges if you are working with a variety of wire sizes.

Features to Look For

Before buying a wire sander, you should consider several factors. You should look for a wire stripper that can handle the gauge range of wires you require. The majority of good models can strip wires between 10 and 24 AWG. Some tools have a built-in length stop. This feature allows you to strip the same amount every time. You can adjust the length of the strips using the swivel knobs.

The ergonomic handles of the tool make it comfortable to use. After long tasks, you will feel less hand fatigue. Some models feature cushioned grips to provide extra comfort. Strong blades will ensure clean cuts and protect the wire. For safe storage, you may need a tool that has a locking system.

Checklist to choose your wire stripper

- Check wire gauge range (10-24 AWG covers most needs)

- Search for the adjustable strip length

- Choose ergonomic handles

- Pick strong, sharp blades

- Consider adding safety features such as locks

Note: Before you buy, always read reviews and compare features. You can save time and effort by using a good tool.

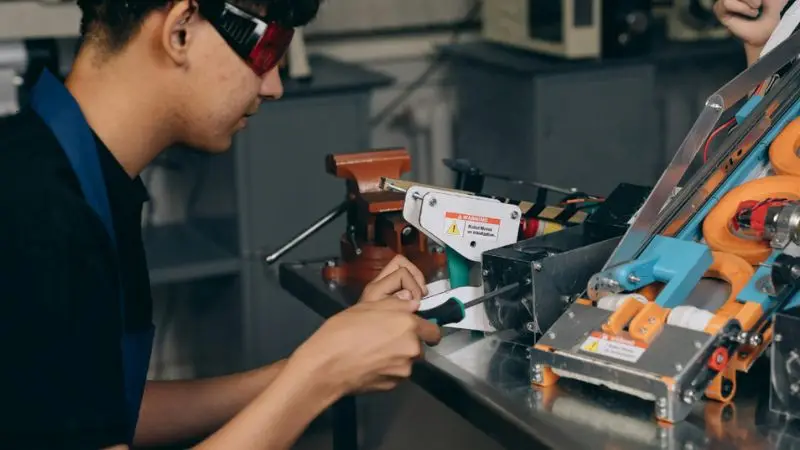

Step-by-Step Guide: How to Use a Self-Adjusting Wire Stripper

The following is the step-by-step guide on the usage of the Self-Adjusting wire stripper.

Preparing Your Wire for Stripping

Start by selecting the right wire for your project. Check the wire to see whether it has been damaged or not. In case there is any dust or grease, wipe the wire with a dry towel. Ensure that the wire is not bent. Bent wires may be more difficult to strip. The measurement of the removal length of insulation that you want can be done. Apply a ruler or the length stop that was installed on your instrument. Organize wires in a line and make them more accessible in case of more than one wire.

Tip: Before starting the work, double-check your wire gauge. By doing this, you will avoid making mistakes and keep your work safe.

Using the Tool for Clean, Accurate Strips

Hold the wire in one hand tightly. Open the self-adjusting wire strippers. You should then place the wire between the jaws where you want to remove the insulation. Squeeze the handles. With a single movement of the tool, the insulation will be stripped off the wire. No adjustments are required. Check the stripped end. The metal must be clean and unaffected.

How to use the tool

- Open the jaws.

- Insert the wire.

- Align the blades.

- Squeeze handles.

- Check the wires that have been stripped.

Do the same thing in case you need to strip a couple of wires. This will guarantee consistent outcomes..

Common Mistakes to Avoid

If you hurry or skip steps, you may make mistakes. Use the tool only on wires within its range. Avoid pressing the handles too hard. The wire can be damaged if you do this. Align the wires with the blades. Uneven strips can result from misalignment. Use the tool only on clean, dry wires. The grip and cut can be affected.

| Mistake | How to Avoid |

| Wrong wire gauge | Check before stripping |

| Misaligned wire | Line up with blades |

| Excessive force | Squeeze gently |

| Dirty or wet wire | Clean and dry first |

Note: Before proceeding with the actual project, practice on a spare wire. You will gain confidence and skill by practicing on spare wire pieces.

Maintenance Tips to Extend the Life of Your Wire Strippers

By taking care of your wire strips, you can extend their life and make them work better. Follow these steps you need to take to maintain your tool.

Cleaning and Lubrication

Wire strippers are subjected to the accumulation of dirt and dust. After every use, wipe the tool with a clean, dry cloth. Rubbing alcohol is used to clean any sticky residue. Dry the tool thoroughly. The moving components are supposed to be smooth. Apply a drop of machine oil on the pivot point. Apply the oil by rubbing the handles a few times. By so doing, the jaws will move readily.

Tip: It is essential that you can clean your tool in case you are working in a dusty or dirty place.

Proper Storage Techniques

Storing your strippers properly will help prevent rust and damage. Ensuring that you store your strippers well will mean that they do not rust or get damaged. Keep your tool in a dry place. Do not leave your tool out in the air or in damp areas. Storage: Use a toolbox or drawers. Other individuals hang their tools on pegboards. Put the lock on the tool before storing. This will maintain the jaws closed and guard the blades.

Here’s a quick checklist for storage:

- Store in a Dry Area

- Use a drawer or toolbox

- If possible, lock the jaws

- Avoid moisture

When to Replace the Blades

Wire strips are clean and sharp blades that yield strips with clean edges. The blades may wear out or be damaged. Should you realize that the tool is not cutting as good or creating rough edges, then there might be a dull blade. Look at the blades to see whether they are spoiled or not. Some wire strippers can be replaced with blades. Use the instructions that the manufacturer has. Alternatively, you might have to purchase another tool when you are unable to replace the blades.

Use the correct tool for the task. The wear and tear is likely to occur faster in wire strippers when they work on hard materials.

You will be able to save money by taking care of your strippers and working in a safer way.

Self-Adjusting Wire Strippers vs. Automatic Wire Strippers

Here is the comparison between self-adjusting and automatic wire strippers

Key Differences

Tool shops can also have both automatic and self-adjusting wire strippers. They can be identical, yet differing in their functions. The differences will also enable you to select the most appropriate tool

| Feature | Self-Adjusting Wire Strippers | Automatic Wire Strippers |

| Adjustment Needed | No manual adjustment | Manual adjustment |

| Wire Gauge Range | Wide (10–24 AWG) | Limited, set by user |

| Speed | Fast, one-step action | Slower, more steps |

| Risk of Wire Damage | Low | Higher if set wrong |

| Ease of Use | Very easy | Needs more skill |

Self-adjusting models grip wires and strip them without changing settings. Insert the wire, then squeeze. When stripping, you have to position the gauge on the automatic wire strippers. You can break the wire should you set the incorrectly.

Tip: Self-adjusting models save you time by reducing mistakes and eliminating the need to change the wire size each time.

Which Tool Is Best for Your Project?

Before you select a tool, consider your project requirements. Self-adjusting wire strippers would be ideal when you have to deal with a variety of wire sizes and when you require the quickest results. Such tools will assist you in making jobs fast and with fewer mistakes.

Automated wire strippers that are automated are suitable in cases where it is needed to strip only one type of wire. Adjust the gauge so that a number of wires of the same type have already been stripped. They are less expensive, and you will have to adjust the gauge every time you switch wires.

When choosing, consider the following:

- You need to strip wires of different sizes.

- You want to achieve fast and repeatable results.

- Are you new to electrical wiring?

Self-adjusting models are the most preferable in case you have the answer to these questions. Automatic strippers are suitable for simple tasks that need only a single size of wire.

Before making a purchase, verify the range of the gauge of the tool. Your work will be safer and easier when you choose the right tool.

Common Questions and Misconceptions

People often get confused about how wire strippers work and which type is best for their project. This section will clear up common questions and misconceptions so you can confidently choose the tool that best fits your needs.

Myths

There are some myths surrounding wire strippers. There are individuals who feel that such tools will never leave wires intact. It isn’t true. Provided that you use the tool correctly, the wire will not be damaged. The metal is not taken, but the insulation is by the jaws. Almost every time, you will see a good strip.

The second myth is that these tools may be applied to certain wires only. They can be used, in fact, in a great number of varieties of wires, including solid and stranded. Most of the models have the capability of dealing with wire gauges of various sizes. There is no need to purchase a different tool for every project.

Self-adjusting wire strippers can be difficult to use, according to some users. You’ll see it is just the contrary. This tool can do most of the work. Plug the tool into the wire and squeeze the handles. You need not have any special skills.

Tip: Before using a new tool, read the instructions carefully. You can avoid making mistakes and achieve the best results by reading the instructions.

Troubleshooting

Wire strippers can cause some issues. These are just a few of the problems that can be easily fixed.

- In case the tool does not strip the insulation, ensure that the gauge of the wire is within the range of the tool. Jaws may not clamp the wire when it is either too thin or too thick.

- Keep the wire straight with the blades so as not to cut into it. Squeeze the handles not too hard. Gentle pressure works best.

- In case the insulation is left behind by the tool, wipe off the jaws and blades. The tool cannot be effective when dirty or with sticky residues.

- If the tool is stiff, drop some lubricant on the pivot. Wipe the oil applying the handles.

| Problem | Solution |

| Wire not stripped | Check wire size |

| Wire damage | Align the wire, use gentle pressure |

| Insulation remains | Clean jaws and blades |

| Stiff movement | Lubricate the pivot point |

If the problem persists, consult the manual or contact the product manufacturer.

Conclusion

Self-adjusting wire strippers enable you to work faster and with fewer mistakes, which will help you accomplish wiring projects with more satisfaction and ease. It is possible to find various models on the internet, find a video about their usage, and apply the model to your next project to see the difference. A self-adjusting wire stripper helps in reducing your workload, speed and lessening the safety hazards, and as soon as you use it, you will instantly notice how it enhances your workflow.

FAQ

How do you know if your wire is compatible with a self-adjusting wire stripper?

Check the wire gauge. Most self-adjusting wire strippers work with 10–24 AWG. You can use them with solid or stranded wires. Read the tool’s instructions for exact compatibility.

Can you use self-adjusting wire strippers for automotive wiring?

Yes, you can use them for automotive wiring. These tools handle common car wire sizes and types. You get clean strips for repairs or installations. Always check the wire gauge before you start.

What should you do if the tool does not strip the wire cleanly?

Clean the jaws and blades. Make sure the wire is within the tool’s gauge range. Align the wire properly before squeezing the handles. Practice on spare wire pieces to improve your technique.

Do self-adjusting wire strippers require maintenance?

You should clean the tool after each use. Add a drop of oil to the pivot point for smooth movement. Store the tool in a dry place. Replace the blades if they become dull.

Are self-adjusting wire strippers safe for beginners?

Yes, beginners can use these tools safely. The design prevents wire damage and makes stripping easy. Read the instructions before you start. Practice on the extra wire to build confidence.