When your manual wire stripping machine jams or the blade becomes dull, you get frustrated. It is important to maintain your machine regularly. This will help it run smoothly and efficiently. You can save time and money by following some simple maintenance tips. Keep your machine clean, and it will last longer. Take care of your machine, and it will perform well each time you strip the wire. Good maintenance is important whether you’re learning how to use a manual wire stripping machine or are already experienced with one.

- Why Maintenance Matters

- Tip #1: Keep the Machine Clean and Free of Debris

- Tip #2: Lubricate Moving Parts Regularly

- Tip #3: Inspect Blades Frequently for Wear and Dullness

- Tip #4: Check Tension and Alignment Settings

- Tip #5: Tighten Bolts, Screws, and Fasteners

- Tip #6: Store the Machine Correctly

- Tip #7: Use the Machine Within Its Intended Limits

- Common Mistakes to Avoid

Why Maintenance Matters

Regular maintenance keeps your equipment running smoothly and prevents unexpected breakdowns.

Benefits of Maintenance

Your manual Wire Stripping Machine should always work properly. Regular maintenance will help you avoid problems and keep your machine running smoothly. You will save money if you use maintenance tips. Avoiding delays will also help you complete wire stripping faster.

You can get many benefits from maintaining your machine.

- Your wire strippers last longer

- The machine runs smoothly and safely

- The number of breakdowns and jams is reduced

- Get better cuts and better wire stripping

- The rusting and corrosion are reduced.

Tip: You can find out about small problems by performing preventive maintenance. Fix them early to keep your machine running smoothly.

Your work will also be better. You can strip wire more easily with sharp, clean blades. Lubricated moving parts allow you to use less force and a quieter machine. By checking and adjusting your machine regularly, you can ensure that every part is working properly. This applies whether you’re using a manual tool or comparing manual vs automatic wire stripping machine options.

Risks of Neglect

If you do not do regular maintenance, you face many problems. While you are using your manual wire stripping device, it can jam up or break. Dull blades will slow you down and can cause wires to be damaged. Unsightly bolts and parts can cause injury or bad results.

This table shows what could happen if you don’t perform maintenance.

| Neglect Result | Impact on Machine |

| Dull blades | Bad wire stripping |

| Rust and dirt buildup | Harder to use |

| Loose fasteners | Not safe to use |

| No lubrication | Parts wear out faster |

It is not worth your time to spend it on problems that you could have avoided. If you skip maintenance, it can lead to expensive repairs or the need for a new machine. Maintaining your manual wire stripping machines will keep them safe and in good working order. This is especially important if you’re running small operations, like an affordable manual wire stripper for home use setup.

Tip #1: Keep the Machine Clean and Free of Debris

Remove Dust and Metal Shavings After Each Use

After using your manual Wire Stripping Machine, you should always clean it to remove any dust or metal shavings. Dust and small pieces of wire can accumulate quickly. These pieces can jam your machine and block moving parts. Use a soft, small brush to remove debris. Some people use compressed air to blow out difficult-to-reach areas. You can keep your machine running smoothly if you clean it regularly.

Tip: After each job, set aside a few moments for cleaning up and removing debris. This simple step will help you avoid larger problems in the future.

Proper Cleaning Tools and Techniques

Cleaning your wire stripping machines requires the correct tools. For loose dust, a soft brush is ideal. Microfiber cloths are great for wiping down surfaces. You can use a wet cloth to remove sticky spots. Use mild chemicals to clean metals. Try a mild solution of soap and water if you notice stubborn grime. Before you can use your machine again, make sure to dry all parts thoroughly.

Here’s a quick cleaning checklist:

- Brush off dust and shavings

- Clean surfaces by wiping them with a cloth

- Mild soap can be used to remove tough spots

- All parts should be dried before storage.

How Cleanliness Prevents Damage and Rust

Cleaning protects against rust and damage. Dust and metal particles can wear out moving parts and scratch surfaces. Rust can be caused by moisture and debris. Rust can make your machine difficult to use and reduce its lifespan. By keeping your machine clean, you can stop rust from starting. You will also ensure that all parts move freely. Regular cleaning will keep your wire stripping machines safe and ready to work. This matters even more in a manual wire stripping machine for recycling businesses where usage is heavy.

Tip #2: Lubricate Moving Parts Regularly

Which Components Need Lubrication

Keep your wire strippers running smoothly. Focus on lubricating moving parts. You should look for parts that move as you hold the handle. The blade assembly, rollers, and pivot points are all examples. You should pay attention to any parts that rub against each other. If your machine is equipped with gears, you should check them. Be sure to check all small levers and springs. Every moving part is important to a smooth operation.

Tip: Make it a habit to check these parts each week. This simple routine will prevent larger problems in the future.

Recommended Lubricants for Manual Wire Strippers

Use the correct lubricant on your wire strippers. Most machines work best with a light machine oil. If you prefer to keep things clean, you can use silicone spray. Avoid using thick grease as it can trap metal shavings and dust. Before choosing a lubricant, always read the instructions. Some machines require a specific oil. Only use a little oil each time. Wipe off any excess oil to prevent it from dripping onto your workspace.

Here’s a quick guide to help you decide:

| Lubricant Type | Best For | Avoid Using On |

| Light machine oil | Blades, rollers, pivots | Plastic parts |

| Silicone spray | Hard-to-reach spots | Electrical contacts |

| Grease | Not recommended | All moving parts |

Signs Your Machine Needs Lubrication

When your machine requires lubrication, you can tell by the sound it makes. It is time to add oil if you hear grinding or squeaking. Dry parts can also be indicated by jerky or hard movements. Check the moving parts immediately if the handle feels stiff. There may be small metal shavings around the joints. The parts may be rubbing together too much. Regular maintenance will keep your machine in good working order and safe. Your manual wire strippers will last longer and perform better with good lubrication.

Tip #3: Inspect Blades Frequently for Wear and Dullness

How to Identify a Dull or Damaged Blade

Check the blades of your wire strippers frequently. Check for signs of damage or dullness. The blade will need attention if you notice nicks, scratches, or uneven edges. A dull blade won’t cut wire cleanly when stripping it. If you notice that the insulation is tearing or has rough edges, your blade may be worn out. The blade may be worn if you experience extra resistance or strange noises.

Tip: Hold the blade in front of the light. If the blade has shiny spots or an uneven surface, it is probably dull.

Sharpening vs. Replacing Blades

When you come across a dull knife, you have two options. You can either replace or sharpen the blade. If the blade is only slightly worn, sharpening will work. Use a fine filing or sharpening stones. Keep the angle constant and move slowly. It is safer to replace the blade if it has deep chips or bends. New blades will give you better results and maintain your machine.

Here’s a quick guide.

| Blade Condition | What to Do |

| Slightly dull | Sharpen blade |

| Chipped or bent | Replace blade |

| Rusty | Replace blade |

Safety Tips When Handling Blades

Always use caution when handling blades. Wear gloves to protect your fingers. If you want to remove the blade, use pliers or other tools to hold it. Keep your fingers far away from the edge. Work on a level surface to prevent the blade from slipping. Keep spare blades in an airtight container. When you sharpen or change blades, never rush.

Note: Cleanse the blade before touching it. Dirt and oils can make the blade slippery and dangerous.

You can avoid problems by performing regular blade checks.

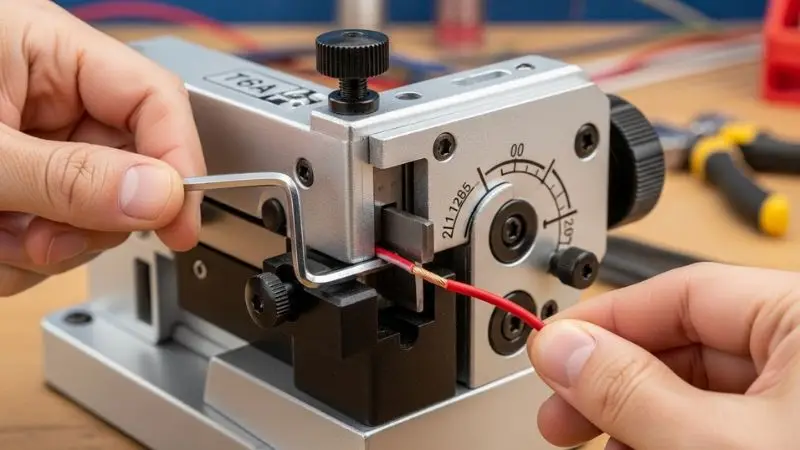

Tip #4: Check Tension and Alignment Settings

Why Proper Alignment Matters for Clean Stripping

Wire strippers should always cut cleanly. The blades will meet the wires at the correct angle if the alignment is done correctly. You may notice uneven or damaged insulation if the blades are not aligned. A good alignment is also important for the safety of the machine. By checking alignment often, you can avoid errors and achieve better results.

Tip: Before you begin a large job, test the machine using a small piece of wire. You can detect alignment issues early.

How to Adjust Tension Depending on Wire Type

Different wires need different tension settings. Set the tension to a lower setting if you are using thin wire. This will prevent the wire from being crushed. Increase the tension for a thicker wire to achieve a clean strip. The tension is controlled by a knob on most manual stripping machines. Test it with a small piece of wire. The wire should move smoothly between the blades. Adjust the tension if the wire gets stuck or slips.

Here’s a quick guide:

| Wire Type | Suggested Tension Setting |

| Thin | Low |

| Medium | Medium |

| Thick | High |

Note: Check the instructions provided by your manufacturer. Some models feature special tension controls.

Troubleshooting Misalignment Issues

If you notice wires or cuts that are not smooth, they may be a sign of alignment issues. This can be a sign that the alignment has been off. Look at the blades, and then the rollers. Check that they are seated straight and not wobbling. Adjust the screws or bolts if you notice gaps or uneven surfaces. Check the alignment of the blades with the wire channel using a ruler. Ask for help or consult the manual if you can’t fix the problem.

Misalignment warning signs that are common

- Uneven wire insulation

- Blades don’t touch the wire evenly

- Machine jams are common

Tip: Checking regularly can help you detect alignment problems before they become serious.

Tip #5: Tighten Bolts, Screws, and Fasteners

Areas Most Prone to Loosening

It is important to know the parts that loosen up most frequently on your manual stripping machine. The handle, blade assembly, and frame joints are all subject to a great deal of movement during use. Every time you strip the wire, these areas vibrate and shake. Bolts and screws can become loose in these areas over time.

Check out this quick list:

- Handle attachment points

- Blade mounting screws

- Roller brackets

- Frame corners

- Tension adjustment knobs

Tip: Check these areas with a small screwdriver or wrench before starting a large job.

How Loose Components Affect Performance

Loose screws and bolts can lead to a variety of problems. You lose control if the handle wobbles. Unstable blades can cause uneven cutting. The machine could jam up or fail to strip the wire. If you ignore these problems, your wire strippers may even be damaged.

Unstable frames can cause the entire machine to be unstable. It can cause safety issues. Your machine should feel stable and solid every time you use it.

This table shows what happens when parts become loose.

| Loose Part | Possible Problem |

| Handle | Poor control |

| Blade assembly | Uneven cuts |

| Frame joints | Machine shakes |

| Roller brackets | Wire slips |

Monthly Maintenance Checklist

A simple checklist will help you maintain your machine. Once a month, set aside some time to inspect all fasteners. Tighten any loose fasteners. Before you begin, remove any dust. After you’ve finished, lubricate the moving parts.

Monthly Checklist

- All bolts, screws, and fasteners should be inspected.

- Tighten all loose parts.

- Remove dust and debris.

- Lubricate all moving parts.

- Test the machine using a scrap of wire.

Note: Check your wire strippers regularly to avoid costly repairs.

Tip #6: Store the Machine Correctly

Protecting Against Moisture and Rust

Keep your manual Wire Stripping Machine clean and dry. Moisture can cause rust, which makes it difficult to use. Before storing the machine, wipe it with a dry cloth. Dry the machine immediately if you notice any oil or water. Keep the machine in an area with low humidity. Silica gel packs can be used to absorb excess moisture. Rust may damage blades and other moving parts. Protecting your machine from water will help it last longer.

Tip: After rainy days, check your storage area. Check to make sure there are no leaks around your wire strippers.

Best Places to Store a Manual Wire Stripping Machine

Choose a place that is safe for your machine. Choose a shelf or cabinet that is dry and clean. Avoid places near sinks, windows, or outdoor doors. Use a dehumidifier in basements and garages to keep your machine dry. Keep your machine out of direct sunlight. Heat can dull blades and warp plastic components. Most machines can be stored in a toolbox or bin.

This table will help you make a decision:

| Storage Place | Good Choice | Bad Choice |

| Dry cabinet | ✅ | |

| Garage floor | ❌ | |

| Toolbox | ✅ | |

| Near window | ❌ |

Using Covers or Cases for Extra Protection

You can use a case or cover to safeguard your manual wire stripping machines. Dust is kept away with a soft cloth cover. A hard case will protect the machine from bumps, drops, and other damage. A case will make it easier to transport your machine if you are traveling with it. You can use a small bag or a cover made for wire strippers. Close the cover or the case when you are finished using the machine.

Note: You can protect your machine from scratches by using covers and cases.

Tip #7: Use the Machine Within Its Intended Limits

Recommended Wire Sizes and Materials

It is important to know what wires are compatible with your manual stripping machine. The majority of wire strippers can handle aluminum and copper wires. Check the user guide to determine the correct wire size. You can damage blades if you use wires too thick or too thin. Wires that are the right size for the machine’s slots and guides will work best. This table shows the most common sizes of wires for correct operation.

| Wire Type | Typical Size Range |

| Copper | 10-22 AWG |

| Aluminum | 12-20 AWG |

| Insulated Wire | 12-22 AWG |

Tip: Test a small section of wire first before you begin a large wire stripping project.

Avoiding Excessive Force or Overloading

Do not force your manual strippers to remove the wires. If you press too hard, the blades and frame can be damaged. Use a gentle, steady press. If the wire does not move smoothly, stop and check the alignment. Overloading the machine and using the wrong material can cause jamming. To keep your operation safe, avoid costly repairs.

- Use gentle pressure

- If you feel resistance, stop.

- Check for jams prior to continuing.

Note: The machine’s lifespan can be reduced if you force it. It will also make the wire stripping process more difficult.

How Proper Use Extends Machine Life

You can prolong the life of a manual wire stripping machine by following the correct steps. Using the right wires and materials will keep your blades sharp. Gentle handling protects the moving parts. Avoiding breakdowns will ensure that wire strippers continue to function smoothly. You will save time and money by respecting the limits set on your machine. Good habits lead to improved results and tools that last longer.

Remember: Proper usage means less downtime and fewer repairs. Your machine will be ready for any job.

Common Mistakes to Avoid

Your manual strippers should work perfectly every time. By avoiding common wire stripping errors, you can keep your machine running smoothly and make your job easier. Here are a few mistakes to watch out for.

Using Dirty or Damaged Wires

Wires that are damaged or dirty can cause problems. Dirt, corrosion, and other contaminants that are on the wires can dull blades, causing the machine to jam. Wires that are broken or bent can damage the blade edge or cause the rollers to jam. Check your wires before cutting. You will get better results and protect your machine if you use clean wires.

Tip: Before stripping, wipe wires dry with a cloth. Check for cracks and bends.

Skipping Lubrication or Blade Care

It’s easy to forget about blade care and lubrication when you are busy. You can reduce the lifespan of your machine by skipping these steps. Moving parts that are dry may grind or squeak. Dull blades will tear insulation instead of cutting it cleanly. Blade inspections and lubrication should be part of regular maintenance. This will ensure that your wire strippers are working safely and smoothly.

Monthly Care Table

| Task | Why It Matters |

| Lubrication | Smooth movement |

| Blade check | Clean cuts |

| Cleaning | Prevents jams |

Ignoring Early Signs of Wear

Minor problems such as uneven cuts or a sloppy handle, may be apparent. Ignoring minor problems can lead you to bigger ones. Early wear may indicate that something is in need of replacement or adjustment. Check alignment if you see jagged cuts. Tighten loose screws right away. Fixing small problems quickly can save you money and time.

Note: Listen for any changes to the sound or feel of your machine. These clues can help you detect problems before they get worse.

You can prevent most wire stripping mistakes by being alert and acting quickly. Maintaining good habits will make your machine run smoothly.

Conclusion

Maintaining your manual wire stripping machine will ensure that they lasts for many years. Clean your machine regularly and add oil to the moving parts. Check for problems with the wire strippers. You can save money by following these steps. Follow the right steps to save money and complete your project faster. Good habits will make your tools safer and your job easier.

FAQ

How often should you follow a maintenance schedule for your manual wire stripping machine?

You should check your machine every month. Regular checks help you find problems early. This keeps your machine working well. It also helps you avoid expensive repairs.

What is the best way to handle the wire stripping setup for different wire sizes?

Adjust the setup before each job. Pick the right slot for the wire size. Test with a scrap wire first. This helps you get a clean strip.

Why is calibration for accuracy important in wire stripping machines?

Calibration helps you make clean cuts every time. You do not damage wires or waste material. Check your machine’s settings often. This keeps your results accurate.

Do you need to worry about checking filters and sensors on a manual wire stripping machine?

Most manual wire stripping machines do not have filters or sensors. If your machine does, check them to keep it running well. This helps stop blockages.

How can you monitor the performance of your manual wire stripping machine?

Watch for smooth operation and clean cuts. Listen for new sounds. If you see problems, check the machine right away. This keeps it working its best.