Knowing how to operate a plasma cutter correctly is the first step to using one safely and successfully. To avoid injuries and get clean, accurate cuts, safety must come first. Strong instruments called plasma cutters are made to cut a variety of metals, including copper, aluminum, and steel.

Although their adaptability enables complex designs and effective processing, the best outcomes require proficiency with a plasma cutter. Before you start, make sure you have the appropriate safety gear, arrange your workspace properly, and check your equipment.

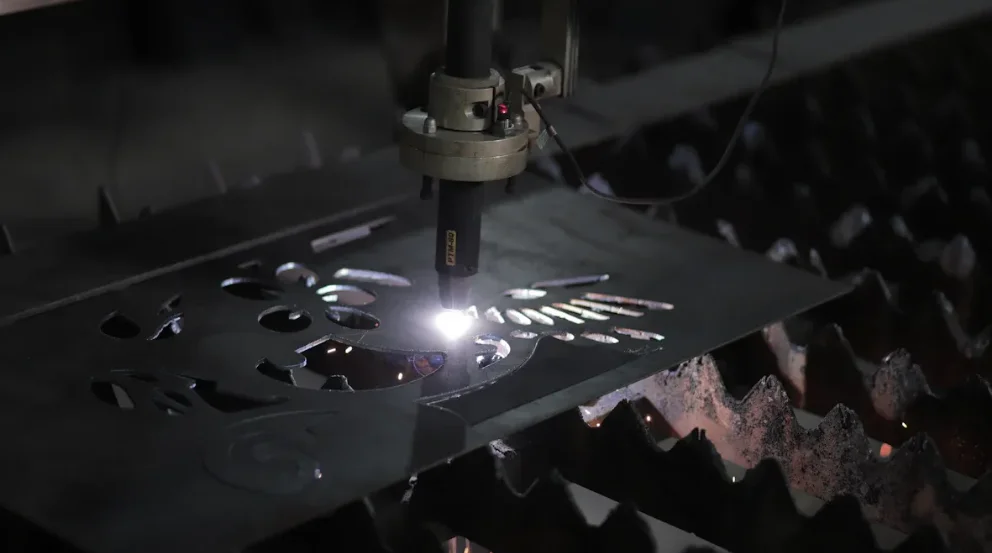

How to Use a Plasma Cutter on Metal

You can get clean cuts and steer clear of errors by learning how to operate a plasma cutter safely and efficiently. Before you begin, there are a few crucial steps you must take. From setting up your machine to modifying your settings, this guide will walk you through every step. For easy tips and best practices on using a plasma cutter, continue reading.

1. Get the machine ready.

Make sure your plasma cutter is prepared first. Attach a reliable power source to the machine. A consistent power source avoids voltage drops and maintains the smoothness of your cuts. If at all possible, use a dedicated outlet. Make sure your plug and power cord are in good shape at all times. Here’s how to comprehend how a plasma cutter operates.

- Systems for machine data capture (MDC) assist you in monitoring cutting data and streamlining your workflow.

- With real-time monitoring, you can identify issues quickly and address them before they lead to mistakes.

- Your plasma cutter will continue to function properly with regular cleaning and replacement of worn parts.

2. Set Up the Workpiece

Your metal workpiece should be placed on a level, sturdy surface. Ensure that it won’t move while being cut. Hold it in place with clamps or magnets. Accuracy and safety both depend on this step.

- Secure workpieces result in better cuts and fewer errors, according to controlled tests.

- Adapt the air pressure and cutting speed to the thickness and type of metal.

- For optimal effects, hold the torch at a constant height above the metal.

- Check your program and do a trial run if you use CNC plasma cutting.

3. Ground and Ensure Air Supply

Attach your metal workpiece to the ground clamp. A stable arc and a lower chance of electric shock are maintained by proper grounding. If you have a professional tester, use them to check the ground connection.

- Particularly in crowded workshops, a steady ground line improves the performance of your plasma cutter.

- Ensure that your air supply is dry and clean. Your cuts can be ruined by airborne moisture or oil.

- Adjust the air pressure according to the size of your metal and tip.

4. Adjust Settings

Set your machine for the metal you want to cut. Adjust the amperage and air pressure based on the thickness and type of metal. Use the table below as a quick guide:

| Tip Size (Amp) | Orifice Diameter (mm/in) | Recommended Amperage (A) | Air Pressure (psi) |

| 20 amp tip | 0.6 mm / 0.025 in | 15 – 20 | 50 – 55 |

| 30 amp tip | 0.8 mm / 0.030 in | 21 – 30 | 55 – 60 |

| 40 amp tip | 0.9 mm / 0.035 in | 31 – 40 | 65 – 70 |

| 50 amp tip | 1.0 mm / 0.040 in | 41 – 50 | 65 – 75 |

| 60 amp tip | 1.1 mm / 0.044 in | 51 – 60 | 65 – 75 |

| 70 amp tip | 1.2 mm / 0.047 in | 61 – 70 | 75 – 80 |

| 80 amp tip | 1.3 mm / 0.051 in | 71 – 80 | 75 – 80 |

Tip: Copper needs about twice the amperage as steel for the same thickness. If you use cnc plasma cutting, enter the right settings in your software. Always double-check your numbers before you start. This step helps you avoid mistakes and wasted metal.

5. Use the Right Cutting Technique

You get the best cut quality from your plasma cutter when you keep the torch tip at the right distance from the metal. Hold the torch about 1/16 inch above the workpiece for most plasma cutting jobs. For thin materials, start with a 1/8 inch gap.

If you cut thicker aluminum, increase the distance to 1/4 inch. Always keep the torch steady and move at a consistent speed. This helps you avoid rough edges and too much slag.

Set the pierce height to 1.5 to 2 times the cutting height to protect your consumables when you start a cut. Make sure the cutting table is clean and level before you begin cutting metal.

Tip: A steady hand and the right torch height give you cleaner cuts and help your plasma cutter last longer.

6. Use Guides and Edges

You can cut the metal in a straight line by using a straight edge or guide. Beside your cut line, place an angle iron or metal ruler. Your hand remains steady and your plasma cutting path remains straight as a result. Keep the torch as near to perpendicular to the metal as you can.

This results in a smoother edge and less beveling. For thin sheets, drag cutting, where the nozzle rests on the metal, works well. To maintain a strong electrical flow, always fasten the ground clamp to clean metal close to your cut.

- Keep a consistent standoff distance for every cut.

- To prevent dross or partial cuts, proceed at a constant pace.

- You can always get the best cut quality with the aid of guides.

7. Trigger Lock and Operation

For safety, the majority of plasma cutters feature a trigger lock. Release the lock only when you’re prepared to cut. This keeps you safe and stops unintentional starts. Press the trigger to begin plasma cutting while holding the torch firmly. Follow your marked line or guide with ease.

Once the cut is complete, release the trigger and put the torch down securely. Before using a plasma cutter, make sure all of your cables and connections are in good condition.

Tip: To avoid electric shock during plasma cutting, proper grounding is emphasized in certified safety guidelines from organizations such as the American Welding Society and NFPA.

Plasma Cutter Safety Tips

Your first concern when using a plasma cutter should be safety. Every time you work, you must adhere to the proper safety procedures. Essential safety equipment, creating a secure work environment, and safety inspections are covered in this section. By following these procedures, you can prevent accidents and maintain the efficiency of your plasma cutting work.

Wear Personal Protective Equipment

Before you begin, you must put on the appropriate safety equipment. This equipment shields you from electric shock, heat, and sparks. This is what you require:

- Welding helmets or safety glasses with side shields shield your eyes from flying metal and sparks.

- Clothing that can withstand flames, such as leather or thick denim, protects your skin from burns.

- When working with hot metal, your hands are protected by heat-resistant gloves composed of tightly woven fabric.

- Steel-toed boots or leather high-top shoes shield your feet from falling objects and sparks.

- Wearing clothing that fits properly reduces the chance of sparks flying.

- With loud plasma cutting noise, hearing protection like earmuffs or earplugs is helpful.

- To avoid electric shock, stand on rubber matting or put on rubber gloves.

Have a Well-Ventilated Workspace Setup

For safe plasma cutting, a well-ventilated workspace is essential. Clean air is maintained and harmful fumes are eliminated. Utilize fume extractors, downdraft tables, or exhaust systems.

- Keep flammable materials out of your safe workspace.

- Keep a fire extinguisher close at hand at all times.

- Gas cylinders should be kept upright and away from heat sources.

- For speedy shutdowns, install emergency stop switches.

- Verify that there is no water or oil in your gas or air supply.

Note: Maintaining a safe workspace keeps you healthy and reduces the risk of a fire.

Additionally, you must adhere to electrical safety protocols. Verify all of the cables and make sure your plasma cutter is properly grounded. For added safety, put on boots with rubber soles.

Inspect Your Equipment Inspection

Make sure everything is in working order before using your plasma cutter. Safety inspections aid in the early detection of issues. What to look for is as follows:

- Check for wear or damage on nozzles, cords, and cables.

- Look for dirt or leaks in the seats, threads, and valves.

- Verify that every connection is tight and clear.

- Check for a firm connection with the ground clamp.

- Examine your safety equipment and replace any worn-out parts..

Be careful not to skip inspections. Accidents can result from broken parts.

Your plasma cutter will continue to function properly with routine maintenance and safety checks. Maintain organization and cleanliness in your workspace. Take all necessary safety precautions and keep abreast of procedures that safeguard both you and other people.

3 Plasma Cutting Maintenance Tips

Keeping your plasma cutter in top shape means you need to follow a good maintenance routine. Regular care helps you get the best results from your plasma cutting projects and keeps you safe. You can avoid many problems by cleaning, checking, and replacing parts before they fail.

1. Clean the Torch

You should clean the torch after every use. Metal dust and slag can build up inside the torch head. This buildup can cause poor cuts and even damage your plasma cutter.

Use a soft brush or compressed air to remove dust from the torch body and leads. Wipe down the outside with a clean cloth. Make sure the nozzle and electrode are free from debris. Cleaning the torch also helps you spot any cracks or wear early.

Tip: Clean the power supply and torch cooling system often. This prevents dust from damaging important parts and keeps your plasma cutting safe and steady.

2. Replace Consumables

Consumables like electrodes and nozzles wear out over time. You should not wait for them to fail. Replace them when you notice a drop in cutting quality. Industry experts say you should change these parts based on performance, not just time.

For heavy plasma cutting, you might need to replace consumables every 4 to 8 hours. Some new electrodes last up to 10 hours, which saves money and reduces downtime. Using high-quality consumables also helps your plasma cutter last longer.

3. Conduct Regular Checks

You need to check your machine often. Look for loose wires, worn cables, and leaks. Make sure the ground clamp is tight and clean. Check the cooling system and water quality if your plasma cutter uses water.

Clean the area around your machine to stop dust from causing problems. Regular maintenance and safety inspections help you catch small issues before they become big ones. This keeps your plasma cutting smooth and safe.

Common Mistakes When Learning How to Use a Plasma Cutter

You can avoid many problems by learning the most common mistakes people make with plasma cutters. These mistakes can affect your cut quality, machine life, and safety.

- Poor grounding leads to unstable arcs and can cause electric shock. Always check your ground clamp before you start.

- Incorrect settings, like wrong amperage or gas pressure, result in rough edges, dross, or incomplete cuts. Follow the operator’s manual for the right parameters.

- Insufficient airflow or using dirty air can damage your torch and lower cut quality. Make sure your air supply is clean and dry.

- Using low-quality or worn consumables causes edge distortion, dross buildup, and torch failures. Inspect and replace each part as needed.

- Torch misalignment or holding the torch at the wrong distance from the metal leads to uneven cuts and more dross.

- Cutting too fast or too slow creates defects like bubbly dross or beveled edges.

- Skipping table maintenance or not securing the torch can cause vibration and poor motion.

FAQ

Which metals can be cut using a plasma cutter?

A plasma cutter can cut copper, brass, stainless steel, aluminum, and steel. Conductive metals are ideal for most plasma cutters. For a complete list of materials that are compatible, always consult the manual that came with your machine.

How can you prevent rough cuts with your plasma cutter?

Maintain a steady pace and hold your torch steady. Adjust the air pressure and amperage according to your metal’s specifications. Before cutting, clean your workpiece. Change out worn-out consumables. You can always get clean, smooth cuts by following these steps.

Does using a plasma cutter require specialized training?

Although a license is not required, you should familiarize yourself with the fundamentals before beginning. Practice on scrap metal, watch safety videos, and read the handbook. Training keeps you safe and helps you avoid mistakes.

Conclusion

You protect yourself and get better results when you follow safety steps every time you use a plasma cutter. Good safety habits, like wearing the right gear and checking your workspace, help prevent accidents. Knowing how to use a plasma cutter the right way saves you time and money. You also get better results on every project.

And of course since you are going to need professional equipment, VEVOR has your back! Check out our Plasma Cutter or browse through our collection and shop away your needs!