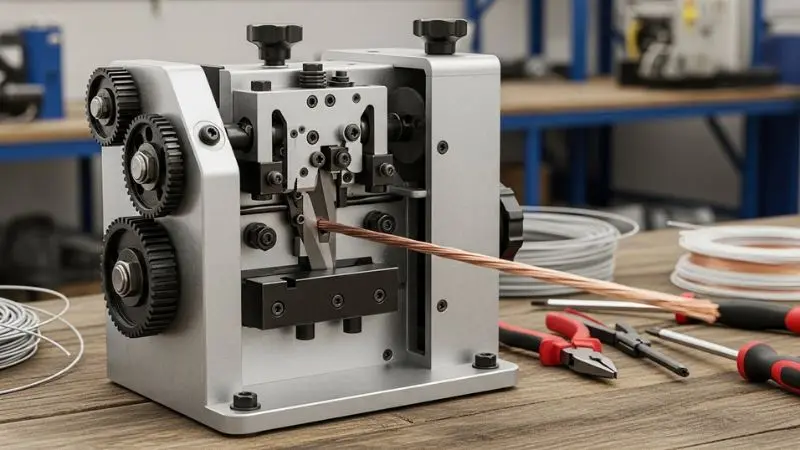

A wire stripping tool is important to cut the wires into smaller pieces. When you like to use your own tools, making a homemade stripper is easy. It is possible to follow the instructions for making a wire stripping tool without having any special skills.

If you are wondering how to make a wire stripping tool at home, try this DIY project. You may be surprised to know that there are very cheap ways to make a wire stripping tool easily.

What You’ll Need to Make a Wire Stripping Tool

Let’s start with the basic tools needed for making an easy DIY wire stripping tool for beginners.

Basic tools and materials list

It’s not necessary to have expensive equipment to make your own wire stripper. The majority of these items can be found in your kitchen or toolbox. Here is a quick list to get you going:

- Utility knife or razor blade

- Small block of wood, or durable plastic

- Screwdriver

- Screws or bolts

- Marker or pencil

- Sandpaper

Pick a hardwood block over soft pine if you want to make a tool that will last.

Choosing the right blade or cutting edge

Your copper Wire Stripper is powered by the blade. It should be sharp enough to cut through the insulation without damaging the wire. Utility knife blades are ideal because they can be easily replaced. Razor blades will also work if handled carefully. Old scissors can be used, but they don’t give a perfect cut.

| Blade Type | Pros | Cons |

| Utility Knife | Sharp, replaceable | Can be tricky to mount |

| Razor Blade | Very sharp, cheap | Fragile, needs caution |

| Old Scissors | Easy to find | May not cut cleanly |

Optional features for enhancing performance

Add a few more features to your wire stripper. You can drill a second hole for different sizes of wire. Attach a clamp to the wire. Some DIYers use a tension knob to gain more control. Consider mounting your tool on a workbench if you intend to strip a lot of wires.

It is important to customize your tool in order to strip wires more quickly and safely. Upgrade your tool to find out what you like best.

How to Make a Wire Stripping Tool (Step-by-Step Guide)

Step 1 — Measure and mark your wire slot

Grab the block that you selected for your wire stripper. Then, place the wire that you wish to stripe on top. Trace a line with a pencil or a marker where the wire is. This mark will show you where to cut the slot. Mark several lines to indicate different sizes if you want to create a tool for stripping wires.

Do not forget to double-check all your marks. Accurate marks will help you achieve clean strips each time.

Step 2 — Shape the tool body

Sandpaper can be used to smooth out the edges of your block. You need a comfortable grip. You can make a tool for wire stripping that is comfortable to hold by rounding off the corners. Drill a shallow groove on the marked line. This groove keeps the wire steady and guides it while you strip.

Step 3 — Install or secure the cutting blade

Place your blade in the groove. It can be secured with bolts or screws. The blade should be snug, but not too tight. Check that the blade is sharp and does not wiggle if you want to create a tool that will last. The blade must only touch the insulation of the wire, not the metal.

Step 4 — Adjust the stripping gap for different wire sizes

Slide a wire into the groove to test the gap. If the blade is cutting too deeply, loosen screws and raise the blade. If the blade doesn’t make enough cuts, lower it. You can use the wire stripper to remove both thick and thin wires with this step. Add extra grooves to your wire stripper for more options.

Step 5 — Test the tool for safety and accuracy

Test your new wire stripper with a scrap of wire. Hold the tool steady, and pull the wire. The insulation should come off easily. Check for any nicks or missing spots if you want a wire stripping device that always works. If necessary, adjust the blade.

Keep your fingers far away from the blade. Wear gloves if you want extra protection.

Tips for Getting Clean and Consistent Wire Strips

Positioning the wire correctly

Every time you use it, it is important to have a clean strip. The wire should be placed flat into the tool’s groove. Place the blade in the groove of your tool. Hold the wire with one hand. Pull the wire with your other hand through the slot. Keep the wire straight to avoid uneven cuts.

First, practice on a scrap of paper. You will learn how much pressure you should use.

Avoiding common stripping mistakes

Most people are too forceful and damage the copper. Let the blade do its work. Check the position of the blade if you notice the wire becoming damaged. Occasionally, the blade is positioned too low. It should only cut the insulation. Check your tool before stripping wire to avoid any problems.

Watch out for these mistakes:

- Cut too deeply and damage the wire

- Use of a dull knife

- The wire is pulled at an angle

- Checking for leftover insulation

How to maintain sharpness and cutting precision

The blade should be sharp to make stripping copper wire easier. If you notice that the blade is tearing or dragging the insulation, replace it. After each use, clean the blade. The edge can be dulled by dust and plastic fragments. Keep your wire stripper dry. Check the blade and screw alignment frequently if you want your tool to work well.

| Maintenance Task | How Often | Why It Matters |

| Replace blade | When dull | Clean cuts |

| Clean blade | After use | Prevent buildup |

| Check alignment | Weekly | Accurate strips |

Note: A well-maintained tool saves you time and keeps your wires safe.

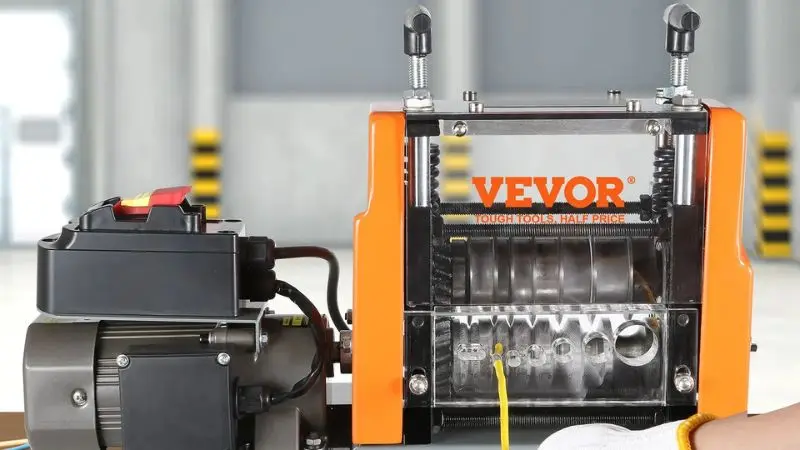

Advanced DIY Wire Stripper Designs (Optional Upgrades)

Adding an adjustable tension knob

You want to have more control over the wire stripping process? Add a tension knob that can be adjusted. This upgrade can be done with a small bolt, a wingnut, and a small nut. Insert the bolt into the hole you drilled above the blade. You can tighten or loosen it using the wingnut. You can use this tool to strip wires with different thicknesses, without having to switch tools. This will result in a smoother strip and less damage to the wire.

Tip: Try the knob on a variety of wire sizes. Adjust the knob until you find a sweet spot for each wire type.

Creating a multi-gauge stripping channel

A multi-gauge channel can save you time if you have to work with many different wire sizes. Create several grooves with different widths in your tool. Each groove corresponds to a specific wire size. Mark each channel so that you can easily identify which one is the correct one. This upgrade transforms your homemade wire stripper into a multipurpose tool.

- Groove 1: Thin wires (speaker wire)

- Groove 2: Medium wires (lamp cord)

- Groove 3: Thick wires

You can change grooves whenever you need to. The blade will not have to be adjusted every time.

Building a bench-mounted wire stripping tool for bulk stripping

Stripping a lot of wire? Make a bench-mounted version. Attach your tool using screws or clamps to a sturdy bench. This allows you to use both hands. With one hand, you can guide the wire and pull it through. Bulk stripping is now faster and safer.

Check that the tool is securely fastened before you begin. Unstable tools can cause injuries.

Common Problems and How to Fix Them

The tool is not cutting through the insulation

Your wire stripper may slide over insulation without cutting. The blade is either too high or dull. Lower the blade slightly. Adjust the screws that hold the blade with a screwdriver. Replace the blade if it still doesn’t cut. In case you want to know how to strip wires without a stripper tool, copper wire can be easily stripped with a sharp blade.

Test your tool first on a scrap of wire before starting your project.

The wire is getting nicked or damaged

Your blade is probably too low if you notice marks or cuts after stripping. The blade should only touch the insulation and not the wires inside. Test again by lifting the blade slightly. Sometimes pulling the wire in an angle can cause nicks. Keep the wire in the groove. You can practice with a few strips until you achieve a neat strip.

Wire damage can be caused by a variety of factors.

- The blade is too low

- Pulling wire at an angle

- Use of a dull knife

Blade alignment issues and how to recalibrate

A crooked knife can ruin your strips of wire. Check the alignment of your blade if you find that your tool is not cutting evenly. Reposition the blade to sit flat in the groove by loosening the screws. Test the tool and tighten the screws. The blade should line up with the wire slot. Use a ruler to verify the position of the blade if you are still having trouble.

Check your wire stripper regularly to ensure it is working properly.

Conclusion

You have just learned how to make a wire stripper tool with simple materials. It is rewarding to make your own tool, and it saves you money. Try it! Share your cool DIY upgrades or results with other DIY enthusiasts. Share your results or cool upgrades with other DIY fans. You may inspire them to begin their own project.

FAQ

Can I use any type of blade for my wire stripper?

Use a utility blade or a razor. Be sure that the blade fits snugly in your tool and is sharp.

What should I do if my wire stripper stops cutting well?

Replace the blade. Remove any debris. Check the blade alignment. A sharp, clean blade always works best.

Is it safe for beginners to make this tool?

Yes! Follow the safety guidelines. Keep your fingers and gloves away from the blade. Start by practicing on scrap wire.