If you have the right copper wire stripping tool, stripping your copper wire becomes much easier. This simple little tool strips insulation off smooth copper without damaging the wire underneath, preparing the wire for a strong and safe connection. If you are home repairing something or involved in a bigger project, having a good tool can save you time, reduce errors, and get better results. Using a good wire stripper makes every cut smoother, every connection prettier, and your entire project faster and safer, from start to finish.

Understanding Copper Wire Stripping Tools

Before handling copper wire for any electrical or recycling project, it can help to know which copper wire tools make everything easier. How your project goes safely and smoothly is already prepared. Get clean, undamaged copper by choosing the right method to strip.

The copper wire stripping tool is intended for removing insulation without damage. It exposes clean copper for wiring, repairs, or recycling. With a cutting tool, if you slice deep, then you will probably break something. But with a stripping tool, you will have more control. No matter whether manual or automatic, the tool provides you with clean and consistent results while keeping the copper in good shape.

Why Wire Stripping Tools Are Important

It helps to understand the importance of stripping tools before deciding on a wire preparation method. Clean wire ensures stronger connections and safer work. A proper stripping technique reduces waste and improves efficiency, particularly with regard to scrap copper.

A copper wire stripping tool for scrap wire protects copper while insulating the wire coating. People often compare manual and automatic wire stripping tools, but both have their benefits, depending on the job. Choosing the best tool for stripping copper wire for recycling guarantees a quick, clean job. With the right tool, copper remains smooth and good for use without unnecessary damage.

Purpose and Function of a Copper Wire Stripping Tool

When you have an understanding of how a stripping tool works, you are able to use it better. The aim is to cleanly remove the insulation while leaving the copper intact. If you use a copper wire stripping tool properly, you will have better results and not damage the wire.

A stripping tool will grip the wire and cut the outer insulation, leaving copper intact. You can adjust the settings to work with different wire sizes, ensuring a cleaner and more uniform result. This tool will save strain on your hands and speed up the workflow. Also, it will get the copper ready for electrical use or recycling. As a result, wire stripping produces consistent and professional-looking results.

Types of Copper Wire Stripping Tools

It helps to know about the types before choosing a tool to prepare the copper wire. Every tool is designed for a specific purpose, and choosing the right one will make your job quicker, cleaner, and safer. The type of wire, insulation, and size of project all play a part in which tool will get you the best result.

Manual Copper Wire Strippers

Manual wire strippers are helpful when you require control and precision to remove insulation. Many professionals test the fit of the wire in the notch before using it so as not to damage the copper below. These tools require hand pressure and are perfect for smaller jobs, repairs, or an occasional stripping job. PVC insulation, MTW insulation, and THHN insulation all work well with crimp connectors. They’re very simple to use and compact, thus they are very easy to carry. Manual strippers offer solid, focused control for home projects and less demanding professional use.

Automatic Copper Wire Strippers

Automatic wire strippers are useful when one needs speed and efficiency. The wire’s insulation is removed by simply inserting it into the tool’s jaws and squeezing it, which happens smoothly without any twisting or pulling. Automatic models adapt to various wire sizes and prevent strain on the hands during repetitive work. People often use these tools when working with larger wire loads or with scrap. The copper wire stripping tool delivers clean and consistent results. This wire stripper is an automatic design that works great when you prepare copper for recycling.

Multifunctional Wire Stripping Tools

Wire stripping tools with many functions are made for people who want this in their tool. They often come with features that allow for cutting, crimping, and bending wire so that you can use them for various jobs within the same project. You can use these tools with many wire sizes and thicknesses of insulation, saving time switching jobs. They don’t require as many tools as some other trades. For someone who values efficiency and flexibility, a multifunctional model can be a great option and works well alongside the best tool for stripping copper wire for recycling when making various types of wires.

Specialty Wire Strippers for Solid and Stranded Wire

Specialty wire strippers are made to safeguard specific wire types. Solid wire has a copper core, and stranded wire has thin strands that will break if mishandled. These tools avoid damage by ensuring the notch pattern and blade depth match the wire style. By switching among the different settings, stripping of insulation occurs cleanly without weakening the copper. You can use specialty strippers for projects where you need more control or a mix of wires. They will deliver consistent performance and can be used with manual or automatic wire stripping tools based on your needs.

Key Benefits of Using Copper Wire Stripping Tools

Before starting any wiring or recycling job, it helps to have an understanding of how the right tool can help you. If the right stripping tools are used, work will be done fast, copper will be better protected, and every task will be easier to accomplish. When wires are prepared properly, safety and performance are enhanced. This advantage is especially important for either installation jobs or recycling scrap copper for reuse.

How Wire Stripping Tools Improve Efficiency and Speed

If you use a stripping tool when working with copper wire, you can work much quickly. A copper wire stripping tool smoothly removes the insulation so you can prepare many wires without losing vigor. This consistency helps you with larger tasks, in which speed counts as well as accuracy. The tool allows you to achieve clean cuts without a knife or scissor struggle. This increases productivity, helps to keep your workspace tidy, and lessens the strain on your body that can be caused by repetitive wiring.

Safety Benefits of Using Copper Wire Stripping Tools

Proper handling of copper wire is critical, and using the correct tools for stripping copper greatly reduces any risk involved. When the tool grips and removes the insulation for you, there is less chance that you will slip or cut your hands. This makes the work routine safer, especially for long hours or high-volume work. A wire stripping tool for scrap wire is healthy since you don’t have to exert pressure or make awkward movements that strain you. With a safer stripping technique, you’ll feel more comfortable and assured during your project.

Why Precision Matters When Stripping Copper Wire

All images and technology-related drawings or graphics will be published on one of our websites. Stripping tools allow you to match the size of the blade to the size of the wire, so you don’t slice through the copper or leave too much insulation on. Something like this would work, or Something similar would work. Both manual and automatic wire stripping tools seek to offer reliable accuracy when compared. With the correct settings on your blades and guided cutting, you can work with the right wiring without damaging the copper.

How Wire Stripping Tools Prevent Copper Wire Damage

Do not let copper wires get damaged at all during the wiring process, as they are valuable for recycling too. A proper tool strips insulation cleanly without marring or bending the internal copper. It makes wire strong and increases the lifespan of electrical connections while reducing scrap preparation waste. Selecting the right tool for stripping copper wire intended for recycling will ensure the copper wire is smooth. With our professional wire stripping services, you can enhance the safety, efficacy, and cost-effectiveness of your project.

Best Way to Strip Wire for Clean, Safe Results

It is helpful to know how wire stripping is done before you cut the wire for any project to give you the cleanest and safest way to go. Good stripping techniques safeguard the copper wiring within your cables for a stronger connection. Whether it’s for home repairs or after handling copper scrap, the right tool makes every step easier thereafter.

Choosing the Right Wire Stripper for Your Project

It’s important to pick the right wire ferret when preparing copper wires for your next electrical job. Your wire, thickness, and the job all influence which tool performs the best. It is better to use a copper wire stripping tool that is made for a cleaner, faster result.

- Pick a tool that best fits the wire size you use the most.

- Think about whether you want an operation under your control or a fast automatic operation.

- Check whether the tool is compatible with PVC, THHN, or MTW type insulation.

If you work with large amounts of wire, automatic models are speedy and consistent, while manual tools are precise for small jobs or detailed work. Using tools that match your workflow gives better protection for your copper but will still give you consistent stripping results.

Proper Wire Stripping Techniques for Smooth Results

The right stripping technique keeps the copper clean and intact. The ideal technique begins with determining the amount of insulation to be removed and aligning the wire to the right notch. Try to grip it tightly with proper pressure so that the conductor below does not get damaged. Preparation of wire or scrap works equally well with this technique.

- Insert the wire into the correct notch for the gauge.

- Don’t squeeze too tightly. Apply enough pressure to cut through insulation.

- Pull the insulation off in a smooth and controlled motion.

With automatic tools, you just put the wire in the jaws and let the mechanism do the stripping job. A correctly stripped wire should be bright and smooth with no nicks. This guarantees a powerful electrical performance and makes it easy to process with the best wire stripping tool.

Maintenance and Care for Wire Stripping Tools

If you take care of your stripping tool, it will stay accurate and streamline your workflow. Clean tools grip better, cut more accurately, and last longer. Even quality strippers need some tune-up to keep them healthy. If you develop just a few simple habits, your tool will be more reliable for everyday wiring or frequent scrap preparation.

- Wipe the tool after use to remove insulation residue.

- Check blades regularly to ensure they remain sharp.

- Keep the tool in a dry place to avoid rust and stiffness.

If you regularly inspect your tires, you can find worn tires before they affect performance. If you work with a copper wire stripping tool for scrap wire all day, you will notice that clean and well-maintained tools make it easier to work safely and consistently.

Common Mistakes to Avoid When Stripping Wire

Many wiring problems start with poor stripping habits. If you avoid making these mistakes, the copper will be protected. Further, the connections will also be stronger and safer. When you are aware of these issues, it will be easier to adjust your technique to get a cleaner wire every time.

Using the wrong notch size can cut the copper.

- Removing too much insulation weakens the wire.

- Pressing too hard reduces precision and damages strands.

- Failing to inspect the wire leads to unnoticed defects.

- Working with dull or dirty tools makes stripping uneven.

When weighing your options between manual vs automatic wire stripping tools, the goal is clean, controlled removal. When you practice on extra wire, it helps you to perfect your technique, so every strip is smooth and safe.

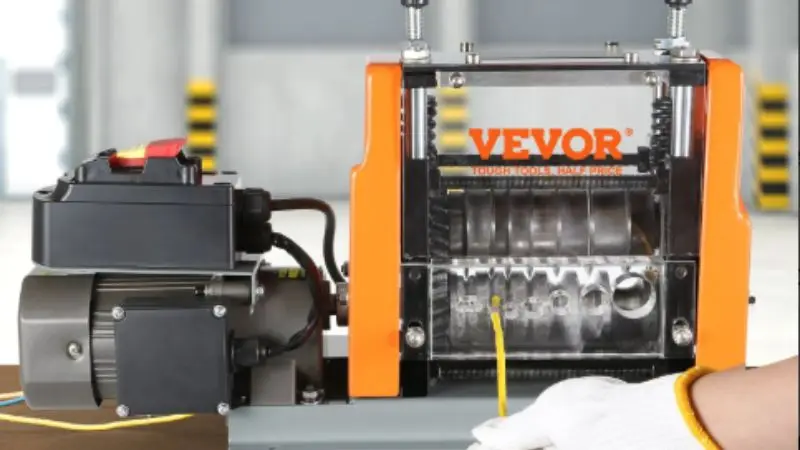

VEVOR Copper Wire Stripping Tools for Easy and Clean Results

It helps to understand why certain brands are preferred over others before choosing a wiring or recycling tool. Many electricians use VEVOR tools because they are fast, accurate, and easy to operate. VEVOR makes tools that simplify wire preparation for at-home and professional installations. That means the copper stays safe while being stripped.

Why VEVOR Self-Adjusting Wire Strippers Stand Out

VEVOR self-adjusting wire stripper makes the stripping process easier by automatically adjusting to wire sizes. You don’t have to mess with blade settings or guess pressure; the tool does most of the heavy lifting for you. It grabs the cable tightly and (with a cut) removes the insulation from it. It is important for the copper inside to be left clean and unscathed so that it will be used electrically or as scrap wire to be used within a copper wire stripping tool.

- Removes insulation quickly with minimal effort.

- Adjusts automatically to various wire sizes.

- Produces consistent, clean stripping results.

- Reduces the risk of damaging copper wire.

Due to its ability to provide accuracy and increased speed, many electricians like this model for long or repetitive tasks. Whether you prepare wires for installation or are destroying scrap, the tool gives consistent results that meet the needs of both beginners and professionals.

How VEVOR Tools Improve the Wire-Stripping Experience

VEVOR tools are intended for those who want clean strips – time after time with little fuss. The self-adjusting feature lets you go from thick to thin wire in no time, which makes big projects faster and smoother. The best tool for stripping copper wire for recycling can easily strip the wire from power cords. Therefore, you can use it for electrical outlets, house wiring, and preparing copper for recycling. Likewise, it’s useful when comparing manual and automatic wire-stripping tools.

- Offers reliable precision for different wire types.

- Helps prevent copper nicks or damage during removal.

- Reduces hand strain during big wiring jobs.

- Supports both home users and professional electricians.

The tool takes care of much of the pressure and alignment, reducing the chances of error and speeding up your workflow. If you frequently work with copper, VEVOR tools are a perfect choice for you to get clean, safe stripping results as per your convenience.

Wrap Up

It’s easier and quicker to strip copper wire with the right techniques and tools. When you go for a manual or automatic self-adjusting option, you can work faster and protect the copper inside. A copper wire stripper tool increases safety, accuracy, and consistency when working with different wire sizes or prepping scrap. Knowing how to use a copper wire stripping tool also reduces errors and gives you cleaner results. By combining quality tools with proper care, every wiring job becomes easier, safer, and more efficient. With the right approach, you will be able to strip wire.

FAQ

What is the safest way to strip copper wire?

You should use a wire stripping tool. Wouldn’t your hands and wires be protected with this tool? Avoid using knives or scissors. Always follow the tool’s instructions.

Can you use one wire stripper for all wire sizes?

Some wire strippers adjust to different sizes. Others have fixed notches. Check your tool’s features before you start. You may need more than one tool for different wire sizes.

How do you clean and care for your wire stripping tool?

Wipe your tool after each use. Remove bits of insulation. Check the blades for wear. Oil moving parts if needed. Store your tool in a dry place.

Why does the wire sometimes get damaged during stripping?

If you don’t use the right notch or press too hard, then the wire gets damaged. Dull blades can also cause damage. Always match the tool to your wire and use gentle pressure.