You use an automatic wire-stripping machine to strip insulation from wires quickly and accurately. This machine is not like a manual or automatic wire stripper. It helps you save time and keeps your hands from getting tired. The device works quickly and makes fewer errors. You need to set it up correctly and watch it work. This helps stop the wires from getting damaged. If you watch closely, you get clean wires with no damage every time.

What Is an Automatic Wire Stripping Machine

You see wires everywhere, from your home electronics to cars and factories. Each wire has an insulating layer that protects it. When you need to connect wires or repair them, you must remove this insulation. An automatic wire stripping machine helps you do this job quickly and safely.

This machine uses motors and sensors to strip insulation from wires without damaging the metal inside. You do not need to use your hands to pull or cut the insulation. The machine does the hard work for you. You just feed the wire into the machine and set the correct size. The machine grabs the wire, cuts the insulation, and pulls it off.

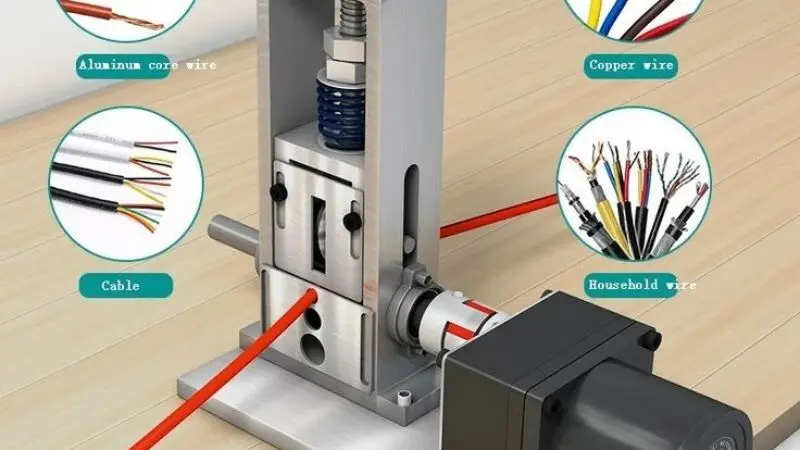

You can use an automatic wire stripper for many types of wires. Some machines work with thin wires, while others handle thick cables. You choose the right machine based on your project. If you use a wire-stripping machine, you save time and get cleaner results than with manual tools.

Here are some reasons why you might choose an automatic wire stripper:

- You want to strip many wires fast.

- You need to avoid hand fatigue.

- You want to reduce errors and waste.

- You need to work with different wire sizes.

A wire stripping machine can help you in schools, workshops, and factories. You can use it for electrical repairs, making new devices, or recycling old wires. The automatic wire stripping machine makes your work easier and safer. You get more accurate results and protect the wire from damage.

Key Components of an Automatic Wire Stripping Machine

When you look at a wire stripping machine, you notice many parts. These parts work together to help you strip wires fast and safely. Let’s look at these principal components.

1. Feed Mechanism

First, you put the wire into the feed mechanism. This part holds the wire and moves it forward. Some machines use rollers, and some use belts. The feed mechanism keeps the wire in place. This helps you get a clean strip every time.

2. Cutting Blades

Cutting blades cut through the insulation but do not touch the metal. You can change the blades for different wire sizes. Sharp knives make copper wire stripping easier and more precise. If the blades are dull, they might hurt the wire or miss some insulation.

3. Stripping Unit

The stripping unit pulls off the insulation after the blades cut it. You see this part work right after the blades finish. The stripping unit makes sure the insulation comes off smoothly. For copper wire stripping, you want this part to be strong but gentle.

4. Control System

You use the control system to set wire length, size, and stripping depth. Some machines have touch screens, and others have buttons. The control system lets you pick settings for different wires. This gives you better accuracy and less waste.

| Component | Function |

| Feed Mechanism | Moves the wire into the machine |

| Cutting Blades | Cuts insulation |

| Stripping Unit | Removes insulation |

| Control System | Sets machine parameters |

| Sensors & Safety | Protects the user and the machine |

5. Sensors and Safety Features

Sensors watch the wire as it goes through the wire stripping machine. If something is wrong, the sensors stop the machine. Safety features protect your hands and keep the machine safe. Always pay attention to these features when using any wire-stripping machine.

Types of Wire Stripping Machines

When you look for a wire stripping machine, you find different types. Each type works best for specific jobs. You should know how each one works before you choose.

1. Pneumatic Wire Stripping Machines

A pneumatic wire stripping machine uses air pressure to move its parts. You connect it to an air compressor. The machine grips the wire and pulls off the insulation. You can use this type for fast jobs. Many people use it for copper wire stripping in workshops. Pneumatic machines work well with small and medium wires. They do not need much electricity. If you wish to recycle, you can use them for copper wire scrap.

2. Servo-driven or electric machines

Motors are used to move the blades and feed the wire in an electric or servo-driven wire stripping machine. On a control panel, you can adjust the length and size. The machine does the rest. You get good accuracy and speed. In factories, this kind is effective for stripping copper wire. It works with a wide range of wire sizes. You can strip multiple cables at once with specific machines.

- Electric machines can be used for wires of any size.

- Servo-driven machines provide better outcomes and greater control.

3. Laser Wire Stripping Machines

A laser wire stripping machine uses a laser beam to remove insulation. You do not need blades or air. The laser burns off the insulation without touching the metal. You get a very clean strip. This type works best for thin wires or wires with special coatings. You often see laser machines in electronics or medical device work. It is also the best automatic wire stripping machine for electricians.

You should match the wire stripping machine to your job. Each type has its own strengths. Think about the wire size, speed, and how clean you want the strip to be.

Wire Stripping Process

How to use a wire stripping machine safely? For optimal results, adhere to these guidelines when using a wire-stripping machine. Every step keeps your wires in good condition and helps you avoid mistakes. This useful guide will help you comprehend the procedure.

Getting the Wire Ready

Examine the wire you wish to strip first. Verify that the wire is straight and devoid of any kinks or bends. Clear away any dirt or debris before working with scrap copper wire. Clean cables provide a better strip and are easier to feed into the machine.

- The length of the wire that needs to be stripped should be measured.

- If necessary, trim the wire to the appropriate length.

- Examine the wire gauge. To assist you in matching the wire size to the proper setting, most machines come with a chart or guide.

Setting Machine Parameters

After that, configure your automated wire stripper. The machine must be modified to accommodate the size and kind of wire you intend to strip. Most machines allow you to adjust the blade depth, wire diameter, and stripping length.

- To enter the wire size, use the dials or the control panel.

- Based on your project’s requirements, determine the stripping length.

- To cut through the insulation without contacting the metal core, adjust the blade depth.

Make sure the machine is ready and the power is on if you plan to use an electric wire stripping machine. Numerous devices can be plugged into a regular outlet and operate on single-phase power. Verify that all safety precautions are in place and that the machine is stable.

Operating the Machine

The automatic wire stripping machine is now ready for use. Put the wire into the feed mechanism. To get the machine to grab the wire, hold it straight and gently push it. While some machines start as soon as the wire is inserted, others have a start button.

- Watch as the machine draws the wire in.

- At the predetermined length, the blades sliced through the insulation.

- The insulation is removed by the stripping unit, exposing the metal.

Change the settings each time you switch to a new gauge if you use different wire gauges. The machine can handle a wide range of sizes, but each requires a different setting. When you match the copper wire stripping settings, the results are the cleanest.

Inspecting the Result

After the machine strips the wire, check your work. Look at the exposed metal. The insulation should come off cleanly, and the wire should not have any cuts or nicks. If you see damage, adjust the blade depth or wire size setting.

- Inspect several wires to make sure the results are consistent.

- If you see leftover insulation, increase the blade depth slightly.

- If you see cuts in the metal, reduce the blade depth.

A good automatic wire stripper gives you fast, accurate results. You save time and avoid hand fatigue. You also get better quality when you strip wires for electrical work, recycling, or copper wire stripping projects.

| Step | What You Do | Why It Matters |

| Prepare the Wire | Clean, measure, and check the gauge | Prevents jams and errors |

| Set Parameters | Adjust length, diameter, and blade depth | Matches the machine to your wire |

| Operate the Machine | Insert wire, start machine, monitor process | Ensures safe, accurate stripping |

| Inspect the Result | Check for a clean strip and no wire damage | Guarantees quality and safety |

By following these steps, you get the most out of your wire stripping machine. You protect your wires, making your work easier and faster.

Conclusion

You can get the best results from an automatic wire stripping machine by following a few key steps:

- Set up the machine for your wire type.

- Watch the process to catch any problems early.

- Use safety gear and keep your hands away from moving parts.

Remember, careful setup and regular checks help you work faster and get clean, accurate strips every time.

FAQ

How can one determine the ideal wire size for stripping?

Before operating the machine, make sure the wire gauge is in good condition. The majority of machines have a chart or guide. Make sure your wire is connected to the appropriate setting. This keeps the strip clean and helps you prevent damage.

Are all wire types suitable for use with an automatic wire-stripping machine?

It works with a variety of wire types. Thin wires are ideal for specific machines. Others manage heavy cables. To find out which wires the machine supports, always consult the handbook.

If the machine jams, what should you do?

Turn off the power first. Gently remove the wire. Clear the feed area and look for any obstructions. After confirming that everything appears to be clear, restart the computer.

How frequently should the machine be maintained and cleaned?

After each use, the machine should be cleaned. Every week, check the blades. Every month, lubricate the moving parts. Regular maintenance helps your automatic wire-stripping machine last longer and work better.

Can novices safely operate these machines?

Yes, even novices can operate these devices. Always read the manual first. Keep your hands away from moving parts and wear safety glasses. For optimal results, adhere to all safety instructions.